MTU Aero Engines is making significant strides in the development of its innovative Flying Fuel Cell™ (FFC), a groundbreaking propulsion concept poised to revolutionize the aviation industry by achieving virtually emission-free flight. This initiative underscores MTU’s commitment to sustainable aviation and its role as a technological leader in pioneering advanced propulsion systems. Through strategic partnerships, rigorous testing, and continuous refinement, MTU is steadily moving closer to the realization of hydrogen-powered, zero-emission commercial flights.

The Flying Fuel Cell: A Deep Dive

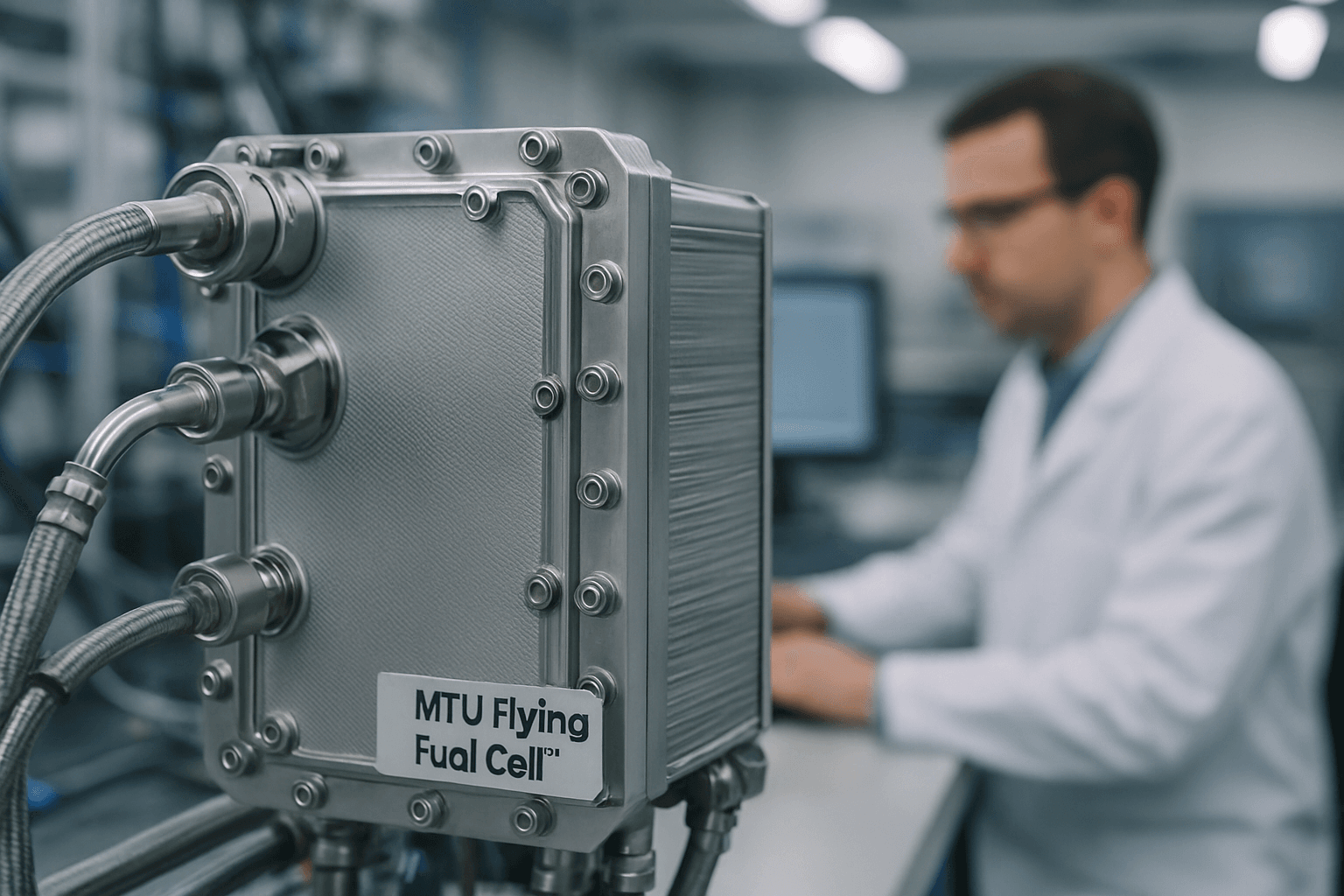

The Flying Fuel Cell™ (FFC) represents MTU Aero Engines’ vision for a sustainable aviation future. Unlike traditional combustion engines, the FFC uses a fuel cell to convert liquid hydrogen into electrical energy. This electricity then powers a highly efficient electric motor, which drives the aircraft’s propeller.

How it Works

The FFC operates on a simple yet elegant principle:

- Hydrogen and Oxygen Reaction: Hydrogen reacts with oxygen from the air within the fuel cell.

- Electricity Generation: This reaction produces water and releases electrical energy.

- Electric Motor Drive: The electricity powers a highly efficient electric motor.

- Propeller Propulsion: The electric motor turns the propeller, providing thrust for the aircraft.

Key Advantages

The FFC offers several compelling advantages over conventional jet engines:

- Zero Emissions: The FFC emits only water, eliminating CO2, NOx, and particulate emissions. This reduces the climate impact of aviation by up to 95%, essentially achieving virtually zero emissions.

- Noise Reduction: With the propeller being the primary source of noise, the FFC significantly reduces overall noise pollution compared to traditional aircraft engines.

- High Efficiency: Fuel cells are inherently highly efficient in converting fuel to energy.

- Recyclability: Platinum used in the fuel cell is highly recyclable and can be reused almost indefinitely when processed properly.

Technical Progress and Milestones

MTU has achieved several significant milestones in the development of the FFC, demonstrating the feasibility and potential of this technology.

Electric Motor Development

MTU’s subsidiary, eMoSys GmbH, acquired in April 2023, is developing a highly efficient electric motor specifically designed for the FFC. This motor boasts impressive specifications:

- Weight: Only 40 kilograms

- Diameter: A mere 300 millimeters

- Continuous Output: 600 kilowatts

- Power Density: 15 kilowatts per kilogram

- Efficiency: Over 96% at continuous take-off power

This electric motor is designed for seamless integration with the fuel cell system, supporting multiple fuel cell stacks without the need for complex inverters. Its fluid-cooled design allows it to operate at temperatures up to 85°C.

Fuel Cell Stack Testing

MTU has established new test facilities at its Munich site to support FFC development. A fuel cell stack test cell, capable of handling 500kW stacks, was recently commissioned. This facility allows for comprehensive testing of fuel cell performance and durability.

Liquid Hydrogen Fuel System

In collaboration with MT Aerospace, MTU is developing a complete liquid hydrogen fuel system for aviation. This system includes:

- Tanks

- Sensors

- Heat exchangers

- Valves

- Safety systems

- Regulators

Multi-week testing of a liquid hydrogen fuel system has been successfully completed, confirming the system’s effectiveness and reliability. These tests, conducted with liquid hydrogen at approximately -250°C, validated the design and functionality of the system, including all necessary sensors and functions for aircraft operation.

HEROPS Project

MTU is leading the Hydrogen-Electric Zero Emission Propulsion System (HEROPS) Clean Aviation research program. This project aims to develop technologies for a climate-neutral, hydrogen-powered electric powertrain for regional airplanes. The HEROPS consortium includes:

- Collins Aerospace

- Eaton

- Lufthansa Technik

- MT Aerospace

- Royal Netherlands Aerospace Centre (NLR)

- Vienna University of Technology

The HEROPS project, which runs from January 2024 to December 2026 with a budget of €40 million (€29 million funded by Clean Aviation), focuses on developing powertrain systems with an output of up to 1.8 megawatts and building a ground demonstrator. The modular architecture of this design is intended to be scalable to between 2 and 4 megawatts.

Design Review and Validation

MTU has completed a preliminary design review for the HEROPS system, marking a significant step towards confirming the feasibility of scaling up its fuel cell technology. The company expects to finalize the design by the end of the year, with 2026 dedicated to the experimental validation of core technologies, including component tests and wind tunnel evaluations of the integrated engine nacelle, propeller, and heat exchanger system.

Revised Testing Strategy

While initial plans involved flight testing the FFC on a modified Dornier 228 aircraft, MTU has adjusted its strategy based on extensive preliminary work and structured design reviews. The company will now focus on subsystem and system tests, utilizing a ground-based validation vehicle and increased wind tunnel testing to validate the design and simulation. Flight tests are still planned but will occur at a later date as part of a product-relevant integration into an aircraft, with the specific test aircraft type yet to be determined. This revised approach aims to avoid disproportionately high costs associated with experimental flight testing in Germany.

Market Entry and Future Applications

MTU anticipates the FFC will initially be deployed on shorter routes in regional air traffic, targeting a market launch around 2035. With improved efficiency, the FFC is expected to expand to short- and medium-haul routes by 2050, further reducing the climate impact of commercial aviation. Initial applications of the fuel cell technology will center on aircraft carrying up to 100 passengers on flights of up to 1,000 nautical miles.

Collaboration and Partnerships

MTU’s success in advancing the FFC is heavily reliant on collaboration and partnerships with leading organizations in the aerospace industry. Key partners include:

- German Aerospace Center (DLR): Collaborating on FFC technology development, with DLR providing a Do228 aircraft as a technology platform and flight demonstrator (though flight test plans have been revised).

- MT Aerospace: Developing a complete liquid hydrogen aircraft fuel system.

- eMoSys GmbH: Developing the highly efficient electric motor for the FFC.

- Collins Aerospace, Eaton, Lufthansa Technik, Royal Netherlands Aerospace Centre, and Vienna University of Technology: Partners in the HEROPS Clean Aviation research program.

- European Union Aviation Safety Agency (EASA): Cooperating on approval requirements for the FFC.

MTU’s Vision for Sustainable Aviation

The Flying Fuel Cell™ is a key component of MTU Aero Engines’ Clean Air Engine (Claire) technology agenda. MTU is committed to developing various concepts for all thrust and power ratings to achieve the aviation industry’s goal of zero emissions. The company focuses on both the evolution of the gas turbine, based on the Geared Turbofan, and revolutionary propulsion concepts like the FFC.

MTU’s CEO, Lars Wagner, emphasizes the company’s commitment to full electrification of the powertrain, identifying the conversion of liquid hydrogen into electricity using a fuel cell as the area with the greatest potential for achieving this goal. MTU believes that developing an airworthy fuel cell presents a significant opportunity, as the experience and data gained in the process will be crucial for further product development.

Challenges and Future Directions

While the Flying Fuel Cell™ holds immense promise, several challenges remain in its development and implementation:

- Hydrogen Infrastructure: Establishing a robust infrastructure for the production, distribution, and storage of liquid hydrogen at airports is essential.

- Fuel Cell Durability: Improving the durability and lifespan of fuel cell stacks for aviation applications is crucial.

- System Integration: Optimizing the integration of the fuel cell system, electric motor, and other components for maximum efficiency and reliability is an ongoing effort.

- Certification: Meeting stringent aviation safety standards and obtaining certification for hydrogen-powered aircraft is a complex process that requires close collaboration with regulatory agencies.

Despite these challenges, MTU Aero Engines remains dedicated to advancing the Flying Fuel Cell™ and other sustainable aviation technologies. The company’s ongoing investments in research and development, strategic partnerships, and rigorous testing programs demonstrate its commitment to shaping a cleaner, quieter, and more sustainable future for air travel.

MTU’s progress with the Flying Fuel Cell highlights the potential of hydrogen fuel cell technology to transform the aviation industry. As the company continues to push the boundaries of innovation, the prospect of emission-free flight is becoming increasingly within reach, paving the way for a new era of sustainable air travel.