In the rapidly evolving field of Unmanned Aerial Systems (UAS), drones have become indispensable tools for surveying and mapping, offering unprecedented efficiency and detail. However, the true bottleneck and a primary consideration in planning any successful drone mapping mission often comes down to a single, crucial factor: battery life. Limited battery endurance directly impacts everything from the size of the area that can be mapped in a single flight to the resolution of the data collected, profoundly influencing mission logistics, costs, and overall project feasibility.

Why Battery Life is the Cornerstone of Drone Mapping Efficiency

The capacity of a drone’s battery dictates its flight time, which is directly proportional to the amount of ground it can cover during a single operation. For professional mapping applications, where extensive areas often need to be surveyed with high precision, short battery life translates into significant operational challenges.

Impact on Area Coverage and Mission Scale

The most immediate effect of battery life is on the achievable coverage area. Drones, particularly multi-rotor systems, typically have flight times ranging from 20 to 45 minutes for commercial models. Fixed-wing drones generally offer longer endurance, covering larger territories more efficiently for agricultural monitoring and infrastructure inspections. When a mission requires mapping a vast expanse, limited battery life necessitates multiple flights, frequent battery swaps, and numerous take-offs and landings. This fragmentation not only extends the total time required for a mission but also increases the logistical complexity and potential for human error. A 30% reduction in battery life, for instance, can significantly reduce the range a UAV can cover.

Influence on Data Resolution and Quality

Achieving high-resolution data often requires drones to fly at lower altitudes, which in turn reduces the area covered per flight and demands more flight lines. This means that for a given battery life, there’s a trade-off between the desired ground sample distance (GSD) – the size of one pixel on the ground – and the total area mapped. If a high GSD is critical, more flights will be needed, making battery longevity even more paramount. Factors like image overlap (typically 75-80% for grid flights) are also essential for accurate orthomosaic generation and directly impact flight duration.

Operational Downtime and Cost Implications

Each time a drone returns to base for a battery swap, valuable operational time is lost. This downtime includes the time spent landing, replacing the battery, and relaunching. For large-scale projects, this can accumulate into significant labor costs and extended project timelines. The need to transport and manage multiple batteries, along with charging equipment, further adds to the logistical burden and operational expenses. Some advanced charging stations can restore batteries to 80% capacity in under 30 minutes, which can help reduce downtime.

Strategies for Optimizing Drone Mapping Missions Despite Battery Constraints

Effective mission planning inherently involves mitigating the limitations imposed by battery life. Several strategies and technological advancements are employed to maximize efficiency.

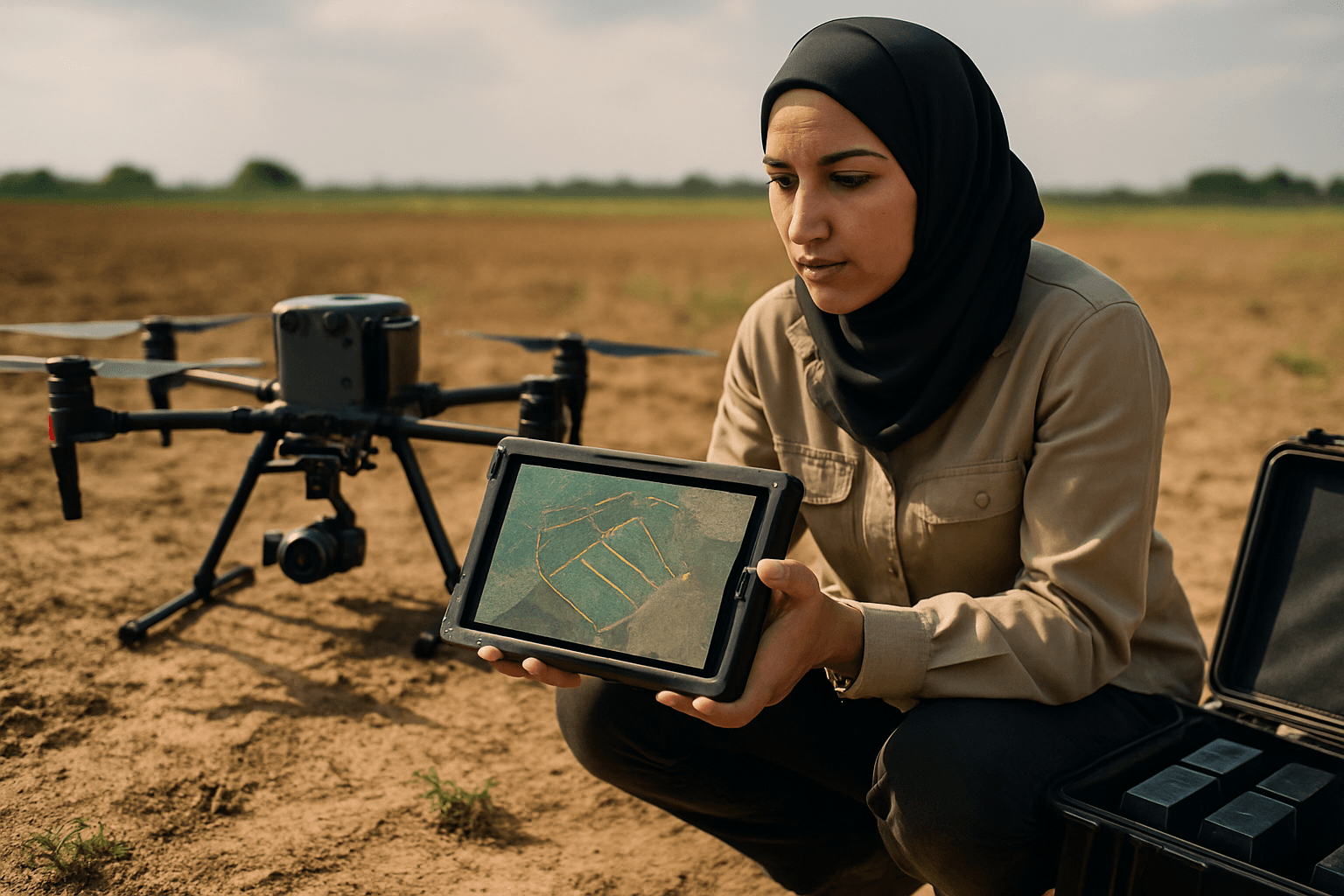

Intelligent Flight Path Planning

Sophisticated flight planning software is crucial for optimizing drone routes. These tools allow operators to define the survey area, specify altitude, and set image overlap, ensuring comprehensive coverage with the fewest possible flights. By minimizing unnecessary maneuvers, changes in altitude, direction, and speed, these platforms can conserve battery power. Some applications can even plan multi-flight missions, estimating the number of batteries required and tracking progress across swaps. For linear infrastructure, corridor mapping optimizes flight paths for efficiency.

Choosing the Right Drone and Battery Technology

The selection of the drone itself, and particularly its battery type, plays a pivotal role. Lithium-ion (Li-ion) and Lithium Polymer (LiPo) batteries are common due to their high energy density and lightweight characteristics. However, not all batteries are created equal; choosing high-capacity batteries specifically designed for the drone model can significantly impact flight time. The weight-to-power ratio is also critical, as heavier payloads (like LiDAR sensors or high-resolution cameras) can significantly reduce flight times. Advanced drones are being developed to carry heavier payloads while maintaining extended flight durations.

Payload Optimization

Reducing the drone’s payload can extend battery life by decreasing the energy required for lift and flight. This might involve carefully selecting sensors or adjusting equipment to be as lightweight as possible without compromising data quality. The balance between payload weight and battery capacity is a crucial consideration for maximizing mission efficiency.

Environmental Considerations

Weather conditions like strong winds and cold temperatures can drastically reduce battery efficiency and flight time. Wind forces motors to work harder, consuming power faster, while cold temperatures reduce the chemical activity in LiPo batteries. Hot weather can also risk overheating electronics and reduce lift efficiency. Mission planning must account for these environmental factors, sometimes requiring higher battery reserves (e.g., 30% instead of 10%) or scheduling flights during optimal conditions (e.g., overcast days or when the sun is overhead to minimize shadows).

Battery Management and Maintenance

Proper battery care is essential for maximizing both flight time and lifespan. This includes calibrating batteries before each flight, storing them in a cool, dry place, and avoiding overcharging or deep discharging. Carrying spare, fully charged batteries is a fundamental practice for uninterrupted survey missions. AI-powered battery management systems are also emerging to predict remaining flight time and optimize maintenance schedules, reducing premature replacements and increasing safety.

Advancements in Drone Battery Technology

The limitations of current battery technology are well-recognized, driving continuous innovation in the field.

Higher Energy Density and Faster Charging

New lithium-ion cells with improved energy density are enabling drones to fly longer without increasing battery weight. Companies are focusing on producing batteries with greater watt-hours per kilogram, alongside fast-charging solutions that can significantly reduce downtime between flights. Developments in materials like silicon or lithium-sulfur are instrumental in achieving higher energy density.

Solid-State Batteries and Hybrid Systems

Solid-state batteries, though still largely in research and development, promise even higher energy density, improved safety, and longer lifespans. Hybrid power systems, such as gasoline-electric multicopters, are also being explored for applications requiring significantly extended endurance, with some achieving flight times of up to 3 hours with substantial payloads.

Smart Battery Management Systems

Modern lithium-ion batteries often include built-in Battery Management Systems (BMS) that optimize energy consumption, prevent overcharging, and enhance safety. Future advancements may include AI-optimized power management that enhances battery life through real-time data analysis.

Conclusion

Drone battery life is not merely a technical specification; it is a pivotal factor that fundamentally shapes the strategic and operational planning of mapping missions. From determining achievable coverage and data resolution to impacting operational costs and safety, battery endurance is at the forefront of considerations for UAS operators. While current limitations necessitate meticulous planning, smart battery management, and strategic use of multi-battery missions, ongoing advancements in battery technology promise to unlock even greater potential for drones in surveying and mapping, transforming them into increasingly versatile and autonomous platforms.