Our global infrastructure, from sprawling bridges and vast power grids to towering wind turbines, forms the backbone of modern society. Maintaining these critical assets has traditionally been a monumental undertaking, often characterized by high costs, significant safety risks, and labor-intensive processes that are prone to human error. However, a revolutionary shift is underway, driven by the powerful synergy of artificial intelligence (AI) and unmanned aerial vehicles (UAVs), commonly known as drones. This combination is transforming how we monitor, maintain, and manage vital infrastructure, ushering in an era of unprecedented efficiency, accuracy, and safety.

The Evolution of Infrastructure Inspection: From Manual to Automated

For decades, infrastructure inspections relied on manual, hands-on methods. Inspectors physically accessed sites, often requiring scaffolding, lifts, or even manual entry into hazardous environments to visually assess conditions and identify issues. This approach was time-consuming, expensive, and posed significant safety risks, particularly when working at heights or in confined spaces. The inherent subjectivity of human visual inspection also meant a higher potential for errors and inconsistencies, with research indicating traditional inspection errors can range from 20% to 30%.

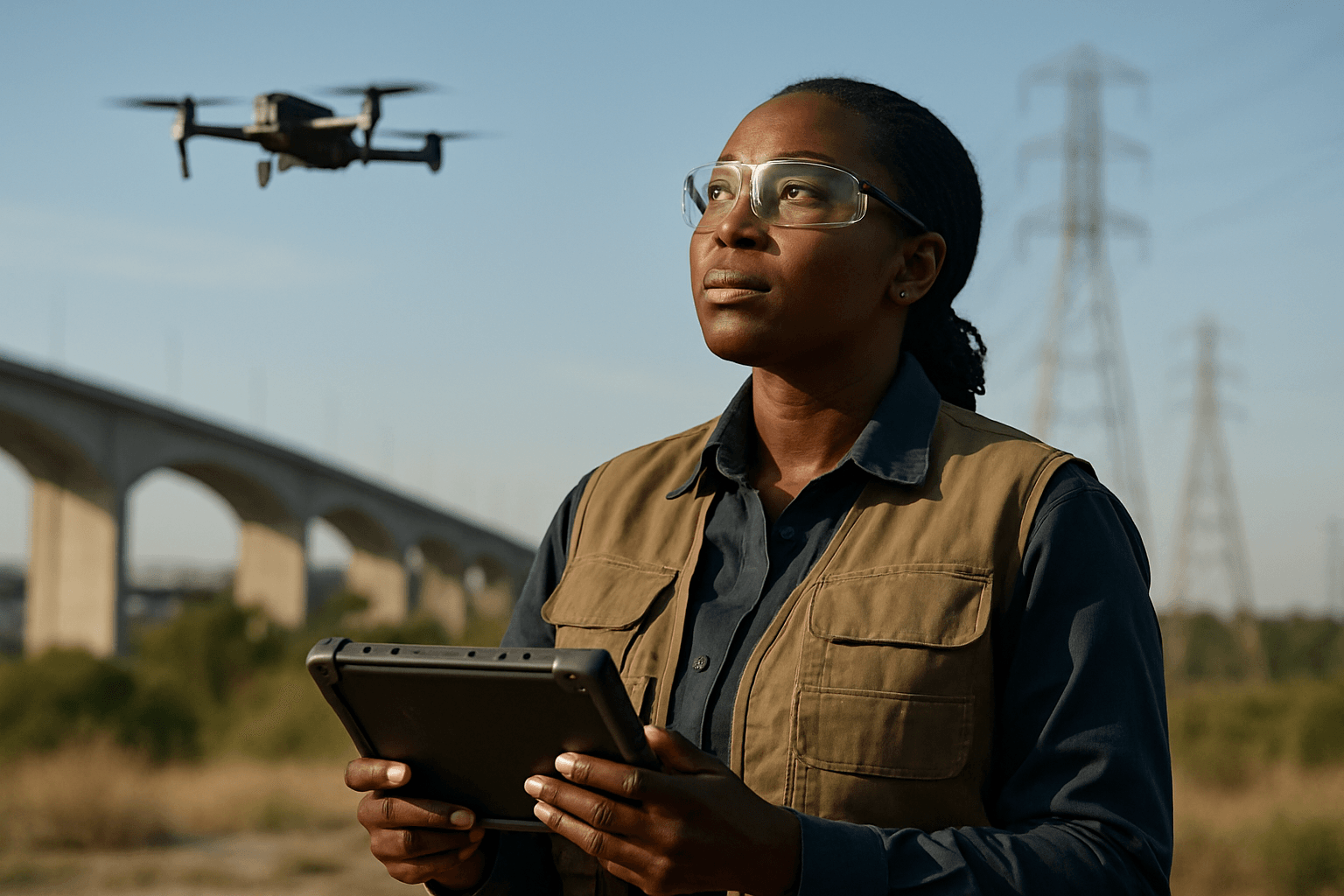

The introduction of drones marked a pivotal shift, initially allowing inspectors to capture images and videos of inaccessible areas without directly exposing themselves to harm. While this improved safety and efficiency, early drone inspections still required manual piloting and post-flight human review of footage to identify problems. The true leap forward came with the integration of AI, empowering modern drones to autonomously navigate, capture high-resolution data, and process vast amounts of information in real-time.

How AI-Powered Drones are Revolutionizing Inspections

AI-powered drones are not merely flying cameras; they are sophisticated analytical tools that enhance every stage of the inspection process.

Data Acquisition and Sensor Integration

Drones equipped with a diverse array of advanced sensors can capture comprehensive data far beyond what the human eye can perceive. These payloads often include high-resolution RGB cameras, thermal imaging cameras to detect heat signatures indicative of malfunctions, LiDAR (Light Detection and Ranging) sensors for creating precise 3D models, and multispectral cameras for specialized analysis. This enables detailed imagery and sensor data collection from multiple angles, even in hard-to-reach areas like beneath bridges or along vast stretches of power lines.

AI for Automated Defect Detection and Analysis

The true power of AI in drone inspections lies in its ability to process the massive volumes of data collected. AI algorithms, particularly those leveraging computer vision and machine learning, are trained on extensive datasets of images and sensor readings to automatically detect, classify, and even quantify structural defects such as cracks, corrosion, vegetation encroachment, and misalignments. This automated analysis significantly enhances accuracy and speed compared to manual methods, reducing human error and ensuring that critical issues are not overlooked.

Predictive Maintenance and Risk Assessment

Beyond simple detection, AI goes a step further by enabling predictive maintenance. Machine learning algorithms can analyze historical and real-time inspection data to identify patterns, forecast when and where maintenance will be needed, and even predict potential failures. This allows authorities and asset managers to prioritize maintenance tasks, address issues proactively before they escalate into costly failures, extend asset lifespans, and minimize downtime. AI can also assign risk scores based on the severity or likelihood of failure, supporting rapid decision-making.

Enhanced Safety and Efficiency

The benefits of AI-powered drone inspections are manifold. They dramatically enhance safety by removing human personnel from hazardous environments like heights, confined spaces, or live power lines. Inspections that once took days or weeks can now be completed in a matter of hours, leading to substantial cost savings by reducing labor, equipment, and logistical planning needs. This efficiency allows for more frequent monitoring, providing a continuous, up-to-date view of asset conditions.

Key AI Technologies Driving Drone Inspections

Several core AI technologies are fundamental to the success of automated drone infrastructure inspections:

Computer Vision

Computer vision is the cornerstone of AI-powered visual inspections. It enables drones to interpret and understand visual information from cameras and sensors. Sophisticated computer vision algorithms, often incorporating Convolutional Neural Networks (CNNs), are trained on vast datasets to perform tasks like object detection, recognition, and classification. This allows the system to pinpoint specific defect types such as cracks, corrosion, or misalignments with high accuracy and a confidence score.

Machine Learning and Deep Learning

Machine learning (ML) and deep learning (DL) algorithms are crucial for training AI models to learn from data and improve over time. In the context of drone inspections, ML models analyze historical and real-time data to identify patterns, predict potential issues, and recommend maintenance actions. Deep learning, a subset of ML, utilizes neural networks to process complex visual data, enabling the detection of subtle defects that might be missed by human inspectors.

Autonomous Navigation and Swarm Intelligence

Advancements in AI also drive autonomous navigation, allowing drones to follow pre-programmed routes, avoid obstacles in real-time, and operate without constant human intervention. This is critical for consistent, repeatable results and covering large areas. Future developments include swarm technology, where multiple drones work in coordination to cover larger areas more quickly, and advanced obstacle avoidance for complex environments. Docked drone systems, where drones launch, inspect, recharge, and upload data autonomously from on-site stations, further enhance this capability.

Applications Across Industries

The versatility of AI-powered drone inspections makes them applicable across a wide range of industries:

Energy Sector (Power Lines, Wind Turbines, Solar Farms)

Inspecting power lines, often spanning vast and remote terrains, is inherently dangerous and costly. AI-enabled drones can autonomously fly along power grids, capturing high-resolution imagery and thermal data to detect issues like loose connections, overheating components, damaged insulators, or vegetation encroachment, helping prevent devastating wildfires. For wind turbines, drones equipped with AI can navigate difficult-to-reach blades, identifying cracks, erosion, or lightning damage, improving safety and inspection accuracy, and minimizing downtime. Solar farms benefit from automated inspections that detect thermal hotspots or damaged panels, even across large arrays.

Transportation (Bridges, Roads, Railways)

Bridges require frequent and thorough inspections to ensure structural integrity. Drones can capture detailed images of bridge structures, including undersides, beams, and girders, identifying cracks, corrosion, and structural damage with millimeter accuracy. For roads and railways, AI-powered drones can detect potholes, track changes in structural conditions over time, and create accurate 3D models for comprehensive assessment. The Korean Railroad Research Institute (KRRI) reports 90% precision in inspection camera images and 100 mm accuracy for defect location using AI-powered drones for railway infrastructure.

Oil and Gas (Pipelines, Offshore Platforms)

In the oil and gas sector, AI drones can inspect vast networks of pipelines for rust, leaks, or cracks, and assess offshore platforms, identifying potential issues far more quickly and accurately than manual methods.

Construction and Utilities

Beyond the specific examples, AI-powered drones are also revolutionizing building maintenance, inspecting facades and roofs for cracks, corrosion, or water damage. In construction, they monitor project progress, ensure compliance with design plans, and detect safety hazards. Utilities widely use them for inspecting transmission towers and substations.

Challenges and Future Outlook

While AI in drone infrastructure inspections offers immense advantages, certain challenges need to be addressed. These include regulatory hurdles, particularly for Beyond Visual Line of Sight (BVLOS) operations in complex airspace, data privacy and security concerns given the sensitive nature of collected information, and the need for robust data management and integration with existing systems. Training and certifying a skilled workforce capable of operating and interpreting AI-powered drone systems is also crucial.

Despite these challenges, the future of AI in drone inspections is exceptionally bright. Ongoing advancements in machine learning, computer vision, and autonomous navigation will enable the detection of even more subtle defects, more precise predictive maintenance, and even automated repair recommendations. The integration of AI with other emerging technologies, such as the Internet of Things (IoT) and 5G connectivity, will facilitate real-time data sharing and collaboration between drones, sensors, and centralized management systems. This seamless integration will make asset management more efficient, responsive, and ultimately, smarter and more sustainable.

Conclusion

The integration of AI into automated drone infrastructure inspections represents a paradigm shift in how we approach asset management. By combining the aerial capabilities of drones with the analytical prowess of AI, industries are achieving faster, safer, more accurate, and more cost-effective inspections. This technological revolution is not just about identifying problems; it’s about transforming raw data into actionable intelligence, enabling proactive maintenance, extending asset lifespans, and significantly enhancing the safety and reliability of critical infrastructure worldwide. As AI continues to evolve, the possibilities for drone-powered inspections are virtually limitless, promising a future where our infrastructure is managed with unparalleled intelligence and foresight.