The rapid ascent of drone technology is transforming logistics, promising faster, more efficient, and environmentally friendly delivery solutions. Yet, for items requiring strict temperature control—such as life-saving medications, vaccines, diagnostic samples, and certain perishable foods—the challenge extends beyond mere speed. Ensuring the integrity of temperature-sensitive deliveries requires sophisticated thermal management solutions to prevent spoilage and maintain efficacy. Drones are now being engineered with advanced capabilities to tackle this critical aspect of cold chain logistics.

The Criticality of Cold Chain Logistics

Temperature-sensitive goods are ubiquitous, ranging from pharmaceuticals that lose potency outside specific temperature ranges to fresh produce that quickly spoils. The “cold chain” refers to the uninterrupted series of refrigerated production, storage, and distribution activities, along with associated equipment and logistics, which maintain a desired low-temperature range. Breaches in this chain can lead to significant financial losses, compromised product quality, and, in the case of medical supplies, serious health risks.

Traditional cold chain logistics can be complex, especially when reaching remote or disaster-stricken areas. Drones offer a revolutionary solution by bypassing congested ground infrastructure and delivering directly to precise locations. However, their operation introduces new thermal challenges, as internal components like batteries and motors generate heat, and external environmental conditions can fluctuate dramatically during flight.

Advanced Thermal Management Systems in Drone Cargo Bays

To overcome these challenges, delivery drones are equipped with specialized thermal management systems integrated directly into their cargo bays. These systems can be categorized into passive and active solutions, often working in conjunction.

Passive Temperature Control

Passive methods rely on materials and design to slow down temperature changes without requiring continuous power. These include:

- Advanced Insulation Materials: High-performance insulation, such as polyisocyanurate, is used in cargo bay construction to minimize heat transfer between the external environment and the internal payload compartment. This helps maintain a stable temperature for extended periods.

- Phase Change Materials (PCMs): PCMs are substances that absorb or release thermal energy as they change phase (e.g., from solid to liquid). They can be designed to maintain specific temperature ranges (e.g., +2°C to +8°C for many pharmaceuticals, or even -78°C for ultra-cold requirements using dry ice alternatives). Companies like Intelsius offer multi-use, temperature-controlled packaging systems like ORCA Drone, which utilize a wide range of PCM solutions to suit various payload requirements.

Active Temperature Control

For more precise and dynamic temperature regulation, especially during longer flights or in extreme weather conditions, active systems are employed:

- Thermoelectric Cooling (TEC) Modules: These solid-state devices use the Peltier effect to create a temperature difference by applying an electric current. They can actively cool or heat the cargo bay, offering precise temperature regulation. Innovative thermoelectric technology, such as Distributed Transport Properties (DTP), can achieve deep cooling, heating, and temperature regulation for drone payloads, often at a lighter weight than conventional methods or dry ice. This technology allows drones to fly farther by reducing payload weight.

- Cooling Fans and Heating Elements: Some drone cargo bays are equipped with miniature cooling fans and electric heating elements that can be monitored and controlled in real-time, allowing users to set and maintain desired internal temperatures.

- Hybrid Systems: Many advanced drones integrate both passive and active methods. For instance, insulation might reduce the overall thermal load, while thermoelectric coolers or fans provide fine-tuned control to keep the payload within a tight temperature range.

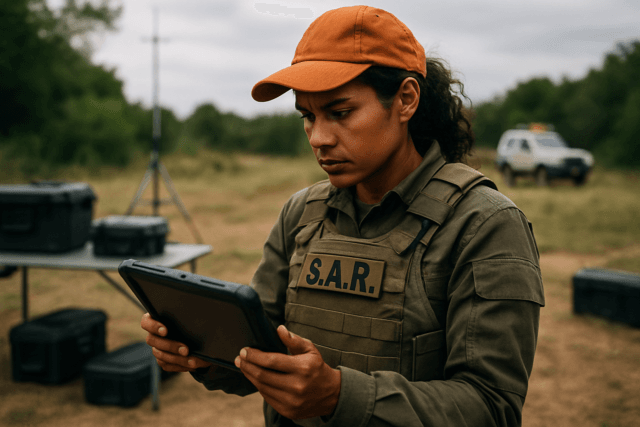

Real-time Monitoring and Data Logging

Beyond physical temperature control, continuous monitoring is paramount for ensuring the integrity of temperature-sensitive deliveries. Drones incorporate sophisticated sensor arrays and communication technologies for this purpose:

- Temperature Sensors: Drones utilize various temperature sensors, including infrared thermal sensors, thermocouples, and thermistors, to measure both internal cargo bay temperatures and external ambient conditions. These sensors can detect minute temperature differences and are critical for maintaining optimal conditions.

- Humidity Sensors: Some drones also include humidity sensors, which can be crucial for understanding environmental conditions and predicting potential issues like icing.

- Real-time Telemetry and Cloud Integration: Embedded loggers and cloud-based technology allow for continuous temperature tracking, real-time data collection, and analysis throughout the flight. This data can include internal temperature, external temperature, exact location, orientation, and battery status. If a temperature deviation occurs, alerts can be sent, and, in some cases, the drone can be programmed to return to a safe location or trigger emergency protocols.

Design Considerations and Environmental Resilience

The design of temperature-controlled delivery drones also takes into account external factors and operational efficiency:

- Weather-Resistant Design: Drones are engineered for endurance and resilience against various weather conditions. While extreme temperatures, strong winds, and precipitation can affect drone performance and safety, advancements include thermal management systems for the drone’s internal components (like batteries and electronics) to maintain optimal operating temperature. For example, some delivery drones are designed to withstand temperatures between -20 and 45 degrees Celsius.

- Payload Capacity and Weight: Thermal management solutions must be lightweight to maximize payload capacity and flight range. Heavy components like dry ice can reduce the amount of product a drone can carry. Innovations in lightweight insulation and thermoelectric systems aim to address this.

- Battery Thermal Management: The drone’s batteries themselves are temperature-sensitive. Both extremely high and low temperatures can degrade battery performance, reduce flight times, and potentially damage components. Therefore, hybrid thermal management systems are often employed to ensure batteries operate within an optimal range, typically 20°C to 30°C.

Leading the Way: Companies and Applications

Several companies and organizations are at the forefront of developing and implementing temperature-controlled drone delivery services. Zipline, for instance, specializes in medical deliveries and utilizes specialized containers for medical supplies, alongside redundant GPS and sensor systems for ultra-reliable navigation. Merck & Co. has successfully piloted drone deliveries of temperature-controlled vaccines at -70 degrees Celsius, demonstrating the technology’s potential for humanitarian aid in remote locations. Amazon Pharmacy is also testing drone deliveries for medications that may require specific temperature ranges.

These advancements are particularly impactful for:

- Pharmaceuticals and Vaccines: Delivering life-saving medications, vaccines, and blood products to remote hospitals or areas with limited infrastructure, often in emergency situations, is a primary application.

- Medical Samples: Transporting diagnostic and biological samples where timely delivery and temperature stability are crucial for accurate testing.

- Perishable Foods: Expediting the delivery of fresh food items, though this area faces similar challenges to medical supplies in terms of maintaining specific cold chain requirements.

The Future of Temperature-Sensitive Drone Deliveries

The drone delivery industry is rapidly evolving, with a clear trend toward more robust and intelligent systems. Future developments are likely to include:

- AI-Powered Predictive Analytics: Integrating AI for smarter flight control and route planning that considers real-time weather conditions and potential thermal impacts.

- Enhanced Battery Technology: Improving battery resilience to extreme temperatures and developing more efficient thermal management for batteries will extend flight times and reliability.

- Standardization and Regulatory Frameworks: As the technology matures, regulatory bodies will continue to evolve frameworks to ensure safety and reliability for temperature-sensitive cargo, allowing for broader adoption.

- Integrated Delivery Ecosystems: The development of climate-controlled drone docking stations, like those by Dronedek, will provide secure, temperature-controlled storage at the delivery point and enable battery charging, addressing “last steps” challenges.

By combining advanced thermal management systems, real-time monitoring, and intelligent flight operations, drones are poised to revolutionize the delivery of temperature-sensitive goods, ensuring product integrity and expanding access to critical supplies worldwide.