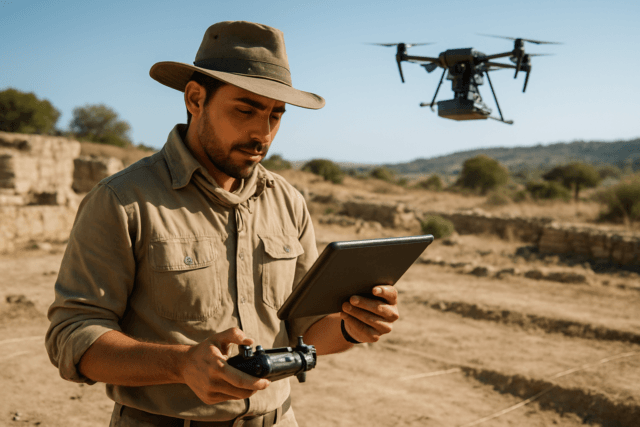

Maintaining critical infrastructure—from bridges and power lines to pipelines and railways—is a monumental and often hazardous task. Traditionally, these inspections were reactive, costly, and put human lives at risk, relying on manual checks that could easily miss subtle signs of degradation. However, the advent of drone technology, or Unmanned Aerial Vehicles (UAVs), has ushered in a new era of predictive maintenance, transforming how these vital assets are monitored and managed. By collecting high-resolution, multi-dimensional data quickly and safely, drones enable asset managers to anticipate failures, optimize repair schedules, and extend the lifespan of infrastructure.

Understanding Predictive Maintenance in the Drone Era

Predictive maintenance (PdM) is a data-driven strategy that anticipates when equipment is likely to fail, allowing for proactive intervention before a breakdown occurs. Unlike reactive maintenance (fixing issues after they happen) or preventative maintenance (scheduled repairs regardless of condition), PdM relies on real-time or near real-time data to identify early signs of degradation and prioritize repairs based on actual risk. Drones are ideally suited for this approach due to their ability to collect vast amounts of precise data from difficult-to-reach or hazardous locations, feeding sophisticated analytics that predict future issues.

Advanced Sensors: The Eyes and Ears of Predictive Maintenance Drones

The core of drone-enabled predictive maintenance lies in the diverse array of sensors they carry. These payloads allow UAVs to capture a spectrum of data, far beyond what the human eye can perceive:

High-Resolution Visual (RGB) Cameras

Standard high-resolution RGB cameras are fundamental for visual assessments, capturing detailed imagery and video of structural conditions. These cameras identify visible defects such as cracks, corrosion, spalling, and general wear and tear on structures like bridges, roads, pipelines, and buildings. Advanced drones are equipped with 4K, 6K, and even 8K cameras, providing exceptionally sharp and detailed visuals for close examination of minor structural defects.

Thermal and Infrared (IR) Cameras

Thermal and infrared cameras are crucial for detecting heat anomalies and temperature variations that are invisible to the naked eye. They are essential for identifying:

- Insulation failures and heat loss in buildings and industrial facilities.

- Electrical faults by pinpointing overheating components in power lines and solar panel installations.

- Moisture detection to uncover dampness or water ingress that may not be externally visible.

- Structural issues by assessing equipment status and potential failure risks.

Thermal drones can also operate in low-light conditions and enhance visibility through smoke or fog.

LiDAR (Light Detection and Ranging) Sensors

LiDAR sensors use laser pulses to generate highly accurate, detailed 3D maps and models of terrain and objects. This technology is invaluable for infrastructure inspection because it can:

- Create precise 3D models of assets, allowing for comparison over time to track changes and deformation.

- Penetrate vegetation to capture the ground surface below, essential for surveying power lines or pipelines running through forested areas.

- Provide accurate data on the position and elevation of various objects for identifying potential risks or structural deformations.

Multispectral and Hyperspectral Sensors

While less common for general structural integrity, these sensors are vital for specific applications:

- Multispectral cameras capture distinct spectral bands (e.g., red, green, blue, near-infrared) and are used for environmental monitoring, such as assessing vegetation health around infrastructure corridors.

- Hyperspectral cameras collect data in hundreds of narrow spectral bands, providing highly detailed information about material composition and characteristics, useful for detecting material degradation or corrosion.

Non-Destructive Testing (NDT) Probes

Some advanced drones can be equipped with NDT probes to detect subsurface flaws or material degradation early, such as signs of corrosion, welding flaws, or thinning metal plates in bridges.

Key Advantages of Drone-Enabled Predictive Maintenance

The adoption of drone technology for infrastructure maintenance brings a multitude of benefits, revolutionizing traditional approaches:

Enhanced Safety

Drones minimize the need for human workers to access hazardous or hard-to-reach areas, such as inspecting tall structures, confined spaces, or high-voltage lines, significantly reducing the risk of accidents and injuries.

Increased Efficiency and Speed

UAVs can cover vast areas in a fraction of the time it would take manual inspections. For example, drones can inspect power line poles in seconds compared to minutes for a lineman, and miles of pipelines or railways can be surveyed in a single flight. This allows for more frequent inspections, leading to earlier detection of issues.

Cost-Effectiveness

By reducing the need for extensive manual labor, specialized equipment (like scaffolding or cherry pickers), and road closures, drones offer a significantly more economical solution for infrastructure inspections. Some reports indicate cost reductions of up to 80% and substantial returns on investment.

Higher Quality and Comprehensive Data

Drones capture high-resolution images, videos, and detailed sensor data from various angles, providing a more thorough and accurate view of the infrastructure. This rich dataset can be used to create highly accurate 3D models and digital twins, offering critical insights for maintenance planning and decision-making.

Real-Time Monitoring and Data-Driven Decision Making

Many drones can transmit collected data in near real-time to ground control stations or cloud-based platforms. This immediate access to information allows for faster decision-making and proactive responses, preventing minor issues from escalating into major problems and minimizing downtime.

Applications Across Critical Infrastructure

Drone technology is being widely adopted across various infrastructure sectors for predictive maintenance:

Bridges and Roads

Drones can easily fly over bridge decks, superstructures, and substructures, scanning for concrete cracks, spalling, and section loss. They can also detect early signs of corrosion or welding flaws in metal bridges. For roadways, drones quickly detect pavement damage like cracking and rutting without closing lanes. This allows engineers to spot tiny cracks and measure structural shifts to predict future damage.

Power Lines and Electrical Grids

Inspecting power lines is traditionally dangerous and time-consuming. Drones equipped with high-resolution cameras and thermal imaging tools monitor power lines for faults, damage, wear, and vegetation encroachment. They can identify hot spots caused by faulty connections or overloaded equipment, enabling timely repairs and preventing outages. One utility company saw an 88% boost in time efficiency and 80% cost reduction using drones for pole inspections.

Pipelines

Drones can oversee miles of pipelines, especially beneficial in remote, mountainous, desert, or forested areas. Specialized payloads locate leaks, cracks, corrosion, and insulation loss in hard-to-access components. This proactive monitoring minimizes the risk of environmental disasters and costly repairs.

Railways

Drones can monitor miles of railway tracks for defects and obstructions, improving operational safety and reducing inspection times without requiring track closures. Some advanced railway drones can even autonomously fly off tracks when encountering other rail traffic.

The Role of Data Analysis and AI

The sheer volume of data collected by drones necessitates advanced data analysis and Artificial Intelligence (AI). Raw drone data, including images, videos, thermal scans, and LiDAR point clouds, is processed and interpreted using specialized software tools. This typically involves:

- Image stitching and 3D modeling: Combining multiple images to create comprehensive 2D maps or 3D models of structures.

- Object detection and tracking: Identifying specific components or anomalies within the data.

- Change detection: Comparing data collected at different times to assess structural changes, wear, or environmental impacts.

AI and Machine Learning (ML) are game-changers in this process. AI-based systems can process vast volumes of data, automatically identifying and flagging minuscule details such as cracks, chips, and general wear and tear. ML algorithms analyze trends, patterns, and anomalies over time, enhancing the ability to predict potential failures. This integration allows for automated defect detection, feeding into digital twins of assets for continuous monitoring and lifecycle management.

Challenges and Future Outlook

Despite the significant advantages, the widespread adoption of drone predictive maintenance faces challenges. These include the high initial investment in drone systems and software, the complexity of managing and analyzing large volumes of data, and integration issues with existing workflows. Regulatory constraints and the need for skilled operators also present hurdles.

However, the future of drone technology in predictive maintenance is bright. Continued advancements in AI, sensor technology, battery life, and autonomous navigation will make drones even more indispensable. The development of swarm technology and enhanced real-time data integration with asset management systems will further streamline operations, ensuring that infrastructure remains safe, reliable, and efficient for decades to come.