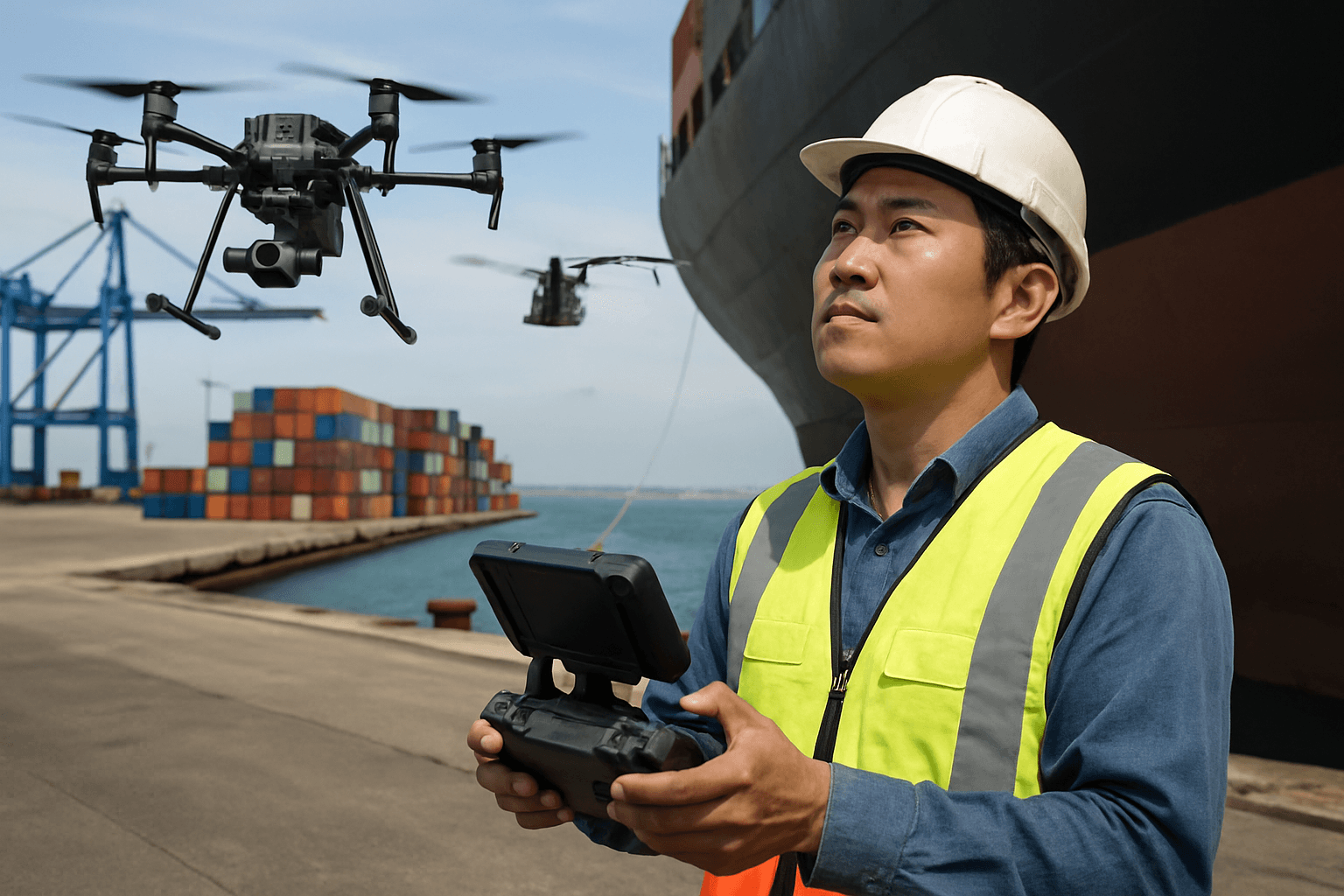

Ports and harbors, vital arteries of global trade, face persistent challenges in maintaining vast infrastructure, ensuring security, and monitoring environmental impact. Traditional inspection methods often prove time-consuming, costly, and inherently risky for human personnel. The advent of drone technology, encompassing both aerial Unmanned Aerial Vehicles (UAVs) and Remotely Operated Vehicles (ROVs), is rapidly transforming these critical operations, offering unprecedented levels of safety, efficiency, and data accuracy.

The Evolving Landscape of Port Inspection

Historically, inspecting the complex infrastructure of ports and harbors—including towering cranes, vast quays, intricate pipelines, and expansive vessel hulls—has been a labor-intensive endeavor. It frequently necessitated the use of scaffolding, cherry pickers, or even human divers, often leading to operational shutdowns and significant safety hazards.

Traditional Methods vs. Drone Advantages

Traditional inspections are characterized by their reliance on manual labor, which can expose workers to dangerous heights, hazardous confined spaces, and challenging underwater environments. These methods are often slow, expensive, and may not provide the comprehensive data needed for predictive maintenance. For instance, inspecting the interior of ship tanks could take hundreds of hours and involve risks from dangerous gases.

Drones, on the other hand, offer a transformative alternative. They can access hard-to-reach or hazardous areas, eliminating risks to human inspectors. Their speed and efficiency allow for quicker coverage of large areas, reducing inspection times dramatically—sometimes by as much as 90% for tasks like ballast and fuel tank inspections. This translates directly into significant cost savings by reducing the need for expensive equipment like scaffolding and cutting down on labor costs and operational downtime.

Key Benefits of Drone-Based Inspections

The adoption of drone technology in port and harbor environments provides a multi-faceted array of advantages that enhance operational capabilities across the board.

Enhanced Safety and Accessibility

One of the most compelling benefits of using drones is the drastic improvement in safety. Drones can inspect areas that are dangerous or inaccessible to humans, such as the top of tall cranes, undersides of piers, or hazardous confined spaces within vessels like ballast tanks. This minimizes risks to personnel, keeping them safely on the ground while critical data is collected.

Cost-Effectiveness and Time Savings

By reducing reliance on scaffolding, cranes, and large inspection teams, drones significantly lower operational costs. Inspections that once took days or weeks can now be completed in hours, leading to faster decision-making and reduced downtime for port operations and vessels. This efficiency allows for more frequent inspections, bolstering preventive maintenance strategies.

Superior Data Collection and Analysis

Drones equipped with high-resolution cameras, thermal imaging, LiDAR, and ultrasonic thickness (UT) sensors provide highly accurate and detailed data. This allows for the precise detection of issues like corrosion, cracks, and structural damage that might be missed by the human eye. The collected data can be used to generate 3D models of structures, enabling in-depth analysis, comparative studies, and robust reporting for long-term record-keeping and predictive maintenance. Real-time data transmission also supports immediate decision-making.

Environmental Impact Reduction

Drones contribute to environmental sustainability by having a smaller carbon footprint compared to traditional inspection methods, as they require less heavy machinery and fuel-powered equipment. They can also be used to detect environmental issues such as oil spills or illegal emissions, allowing for timely intervention and mitigation. For example, the Port of Klaipėda used drones equipped with sensors to monitor ship exhaust gas quality, detecting violations and measuring sulfur content.

Diverse Applications of Drones in Ports and Harbors

Drones offer a wide range of applications that cater to the multifaceted needs of port and harbor management.

Infrastructure Integrity Checks

- Quays, Piers, and Breakwaters: Drones can easily inspect the condition of marine structures like quays, piers, and breakwaters, identifying potential problems for maintenance and repairs. Both aerial drones (UAS) and underwater ROVs are utilized for this purpose.

- Cranes: Inspecting large maritime cranes is safer and more efficient with drones, eliminating the need for humans to climb these structures and allowing for pinpointing structural defects.

- Vessel Hulls and Tanks: Underwater drones (ROVs) can perform hull inspections on passing vessels, checking the condition of hull markings, rudders, sacrificial anodes, and propellers, removing the need for divers and avoiding costly drydock delays. Drones can also inspect confined spaces like ballast and fuel tanks for corrosion and structural damage, providing visual and ultrasonic thickness (UT) data.

Container and Cargo Monitoring

Drones can assist with real-time tracking of ship locations and movements, reducing reliance on radar data. They can also monitor containers, providing data on their movement and assisting with inventory assessments in warehouses and port management. AI combined with drones can even help predict potential collisions.

Security and Surveillance

Drones are invaluable tools for surveillance and security, providing aerial supervision of port activities, detecting unauthorized access, and monitoring borders. They can capture real-time views from various angles, even locating individuals using infrared sensors at night. Their use extends to tracking illegal fishing practices, drug trafficking, and supporting law enforcement in maritime joint arrest operations.

Environmental Monitoring

Beyond emissions, drones are increasingly used for broader environmental monitoring. They can detect oil stains in water, monitor water quality, identify microplastic pollution, and oversee loading operations to prevent cargo particles from falling into the water. This real-time quantification offers valuable insights for environmental management.

Navigational Aid Inspection

Drones can confirm the position, condition, and light characteristics of navigational aids like buoys, extending beyond current inspection uses.

Essential Drone Technologies for Port Environments

The effectiveness of drone inspections hinges on the appropriate selection of drone types and their integrated sensor payloads.

Drone Types

- Multirotors (Multi-copters): These are the most common for inspection due to their maneuverability, ability to hover, and Vertical Take-Off and Landing (VTOL) capabilities, making them ideal for confined spaces and detailed inspections.

- Fixed-Wing Drones: While less maneuverable for close-up inspections, fixed-wing drones offer greater autonomy and are suitable for covering large areas quickly, such as surveying coastal environments.

- Underwater ROVs: Essential for sub-surface inspections, these tethered or autonomous vehicles are equipped with cameras, sonar, and other sensors to inspect hulls, underwater infrastructure, and even measure hull thickness.

Sensor Payloads

The “brain” of a drone inspection system lies in its sensors:

- High-Resolution RGB Cameras: Capture detailed visual data for identifying surface defects, corrosion, and general condition.

- Thermal Imaging Sensors: Detect temperature irregularities, which can indicate structural issues, gas leaks, or overheating equipment.

- LiDAR (Light Detection and Ranging): Creates highly accurate 3D maps and models of structures, useful for comprehensive analysis and volume measurements.

- Ultrasonic Thickness (UT) Sensors: Used with ROVs and some aerial drones to measure the thickness of metal walls, particularly in tanks and hulls, to identify corrosion or cracks.

- Gas Detection Sensors: Crucial for inspecting confined spaces like tanks where dangerous gases might be present.

- Sonar Systems: Primarily for underwater ROVs, used for mapping and detecting objects beneath the water surface.

- Multi-spectrum Cameras: Beyond visible light, these capture infrared and near-infrared spectrums, useful for specialized environmental or agricultural monitoring.

Software for Data Processing and Analytics

Advanced software and Artificial Intelligence (AI) are crucial for processing the vast amounts of data collected by drones. AI algorithms can analyze visual data to identify defects, track objects, and even predict potential collisions, streamlining operations and enabling predictive maintenance. This includes automated defect detection, 3D model generation, and comprehensive report creation.

Challenges and Considerations for Drone Deployment

Despite the numerous advantages, deploying drones in port and harbor environments presents several challenges that require careful consideration.

Regulatory Compliance and Airspace Management

Ports often lie within controlled airspace, especially near airports, necessitating strict adherence to aviation regulations. Operators must obtain appropriate permits and authorization from aviation authorities like the FAA (Federal Aviation Administration) and local port authorities for commercial operations. Some ports have specific drone policies, and operating near sensitive environmental areas might require additional permissions.

Environmental Factors

The maritime environment presents unique challenges for drone operations. Drones must be engineered to withstand harsh weather conditions, including strong winds, heavy rain, and salt spray. GPS interference can also be an issue in complex port structures. Additionally, certain areas within ports may be classified as ATEX (explosive atmosphere) zones, requiring intrinsically safe and ATEX-rated drones to prevent fires or explosions.

Data Security and Privacy

The increasing use of drones for surveillance and data collection raises concerns about data security and privacy. Ports must implement stringent measures to prevent hacking of drones or unauthorized access to their data streams. The potential for malicious use of drones for unauthorized surveillance or even weaponization is a significant security risk.

Implementing a Successful Drone Inspection Program

To effectively integrate drones into port and harbor operations, a structured approach focusing on training, standardized procedures, and data management is essential.

Pilot Training and Certification

Commercial drone operators are generally required to pass certification exams (e.g., FAA Part 107 in the US) and adhere to specific guidelines. Training courses prepare pilots for complex industrial inspection environments, covering aspects like pre-flight checklists, flight planning, camera choices, and emergency procedures. Skilled pilots and visual observers are crucial for safe and efficient operations.

Developing Standard Operating Procedures (SOPs)

Establishing clear Standard Operating Procedures (SOPs) is vital for consistent and safe drone operations. These procedures should cover permit application processes, risk assessments, flight plans, communication protocols, and emergency responses. Many ports are developing or already have specific drone policies.

Data Management and Integration

Effective data management ensures that the information collected by drones is properly stored, analyzed, and integrated into existing maintenance and operational workflows. This includes utilizing software for data processing and analysis, creating detailed reports, and leveraging insights for predictive maintenance and long-term planning.

By strategically leveraging drone technology, ports and harbors can significantly enhance safety, improve efficiency, reduce costs, and gain unprecedented insights into their vast and complex operations, paving the way for a smarter, more sustainable maritime future.