The integration of drones into precision agriculture has revolutionized farming practices, offering unprecedented capabilities for monitoring crops, optimizing irrigation, and applying inputs with precision. However, this technological leap introduces a complex, often unseen challenge: electromagnetic interference (EMI) originating from drones and its potential impact on sophisticated farm equipment. Understanding and mitigating these electromagnetic interactions is crucial for ensuring the reliable, safe, and efficient operation of modern agricultural systems.

What is Electromagnetic Interference (EMI)?

Electromagnetic interference, or EMI, refers to any disturbance or disruption of an electronic system caused by an external electromagnetic field. This interference can degrade the performance of electrical circuits and communication systems, potentially leading to malfunctions, data loss, or signal disruption. EMI can arise from natural sources like lightning or solar storms, but more commonly, it originates from man-made devices such as motors, power lines, and communication equipment.

In essence, EMI occurs when electromagnetic waves generated by one device overlap with the frequency bands of another, leading to a scramble of signals that can compromise functionality. This disruption can occur through conduction (where interference flows through connected cables) or radiation (where electromagnetic waves are emitted through the air).

Drones in Precision Agriculture: A Double-Edged Sword

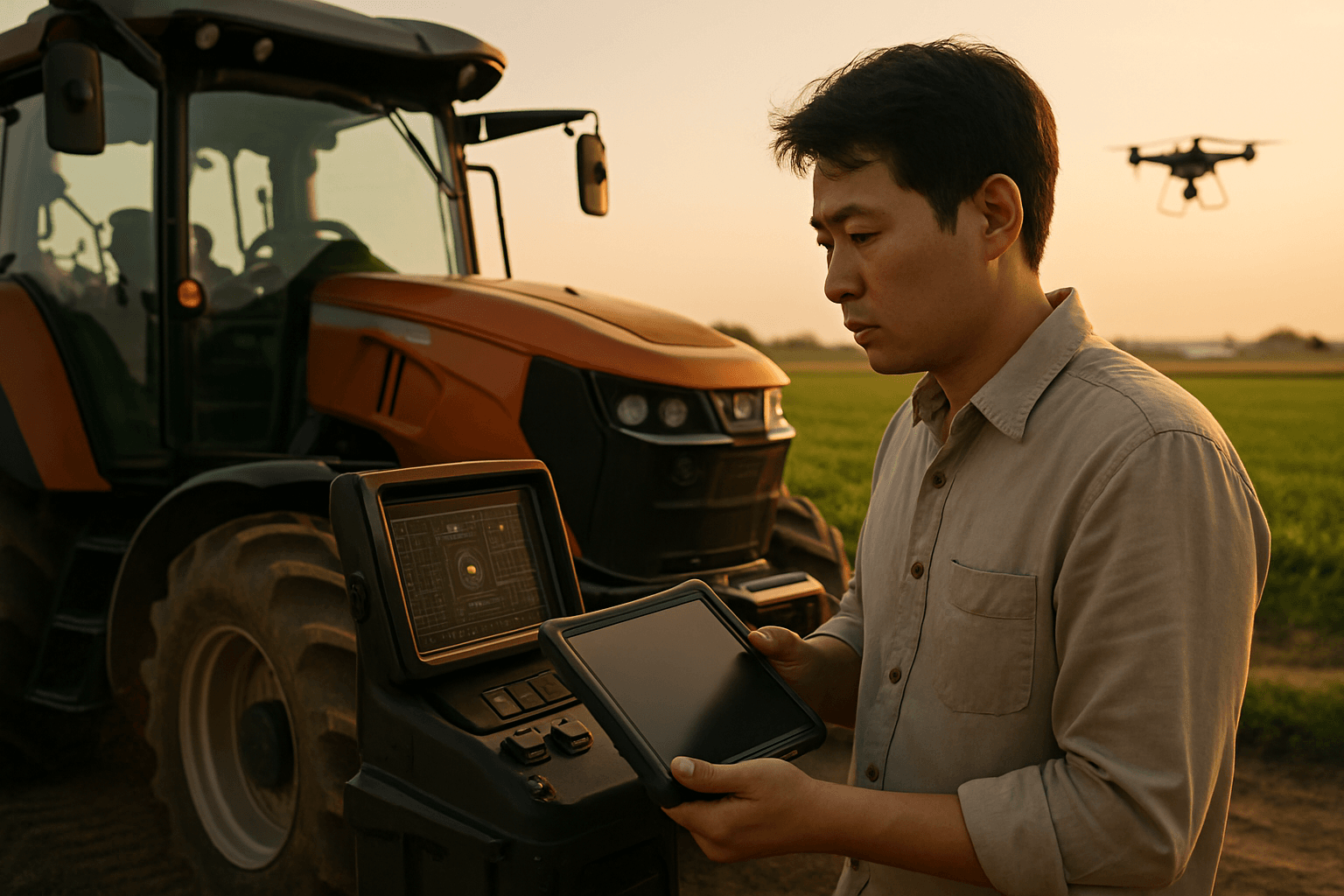

Drones, also known as Unmanned Aerial Vehicles (UAVs), have become indispensable tools in modern agriculture, enabling tasks like detailed crop monitoring, targeted pesticide application, land surveying, and even remote charging of IoT devices. They offer farmers real-time data to make informed decisions, optimize resource use, and enhance overall productivity.

However, the very electronic sophistication that makes drones so valuable also makes them potential sources of EMI. As these systems become more integrated and ubiquitous, their susceptibility to, and generation of, electromagnetic interference becomes a significant concern for the safe and stable operation of both the drones themselves and other sensitive farm equipment in their vicinity.

Sources of EMI from Drones

Drones are packed with electronic components that can generate electromagnetic fields, leading to EMI. Key internal sources include:

- DC Motors and Electronic Speed Controllers (ESCs): The rapid switching of currents in brushless DC motors and their associated ESCs creates significant electromagnetic noise.

- Sensors and Inertial Measurement Units (IMUs): Components vital for flight stability and navigation, such as IMUs (which include gyroscopes and accelerometers), cameras, and altimeters, are susceptible to and can generate electromagnetic signals.

- Printed Circuit Board Assemblies (PCBAs): These control boards, along with transistors and gate drivers, are integral to a drone’s operation and are sources of EMI through both conduction and radiation.

- Communication Systems: The radio frequency (RF) communication links between the drone and its ground control station, essential for control and data transmission, are particularly vulnerable to and can contribute to EMI.

Beyond a drone’s internal components, external environmental factors can also cause EMI to affect drone performance, such as proximity to power lines, cell phone towers, and dense Wi-Fi networks.

Farm Equipment Susceptibility to Drone EMI

Modern farm equipment, especially that used in precision agriculture, relies heavily on advanced electronics, sensors, and communication systems. This dependency makes them vulnerable to electromagnetic interference. Equipment most susceptible includes:

- Global Positioning System (GPS) Receivers and GNSS Sensors: These are fundamental for precise navigation, planting, spraying, and harvesting. GPS signals are relatively weak and can be easily disrupted by EMI, leading to loss of positional accuracy or complete GPS lock. This can cause GPS-guided tractors and other machinery to lose their ability to accurately determine their position.

- Automated Guidance and Steering Systems: These systems use GPS and other sensors to guide farm machinery with high accuracy. EMI can cause these systems to malfunction, leading to off-course driving, overlapping passes, or missed areas.

- Sensors (Soil, Crop Health, Environmental): Precision agriculture deploys a variety of sensors (e.g., soil moisture, nutrient content, pH, multispectral cameras on drones for crop health) that provide critical data. EMI can cause these sensors to provide incorrect readings or fail entirely, compromising data integrity and decision-making.

- Control Units and Communication Networks: The electronic control units (ECUs) that manage various farm implement functions and the wireless networks connecting IoT devices across the farm are also at risk. EMI can distort signals, leading to operational failures or delays in control commands.

Implications of EMI on Farm Equipment

The interference generated by drones can have significant and wide-ranging implications for farm operations:

Operational Failures and Reduced Accuracy

EMI can directly interfere with the functional performance of automation systems in farm equipment. This can manifest as signal distortion, leading to reduced accuracy in tasks like seed placement, fertilizer application, or pesticide spraying. In extreme cases, it can cause complete operational failures of machinery. For instance, if a drone’s EMI affects a tractor’s GPS, the tractor might deviate from its programmed path, resulting in misapplication or missed areas, which directly impacts crop yield and resource efficiency.

Loss of Critical Data and Control

Drones often collect vast amounts of data—from multispectral imagery to thermal readings—which are then transmitted for analysis. EMI can corrupt this data or disrupt the communication links necessary for transmission, leading to incomplete or inaccurate information for farm management decisions. Moreover, EMI can interfere with the control signals between an operator and remote or autonomous farm equipment, potentially causing loss of control or erratic behavior.

Increased Downtime and Maintenance Costs

When farm equipment malfunctions due to EMI, it leads to increased downtime, delaying critical operations during tight planting or harvesting windows. This can result in significant economic losses for farmers. Furthermore, chronic exposure to EMI can cause wear and tear on electronic components, leading to increased maintenance costs and potentially decreasing the lifespan of valuable farm machinery.

Safety Hazards

Erratic behavior or sudden loss of control in large farm machinery or even in the drones themselves due to EMI poses considerable safety risks to operators and others in the vicinity. Unpredictable movements of autonomous tractors or malfunctioning sprayers could lead to accidents or improper application of chemicals.

Economic Impact

Ultimately, all these factors converge into a significant economic impact. Reduced yields due to inaccurate applications, wasted resources (fuel, seeds, fertilizer, pesticides) from operational errors, increased repair costs, and lost productivity from downtime all contribute to higher operational expenses and diminished profitability for agricultural enterprises.

Mitigation Strategies for Drone EMI in Agriculture

Addressing drone EMI requires a multi-faceted approach, combining careful design, operational best practices, and adherence to evolving standards.

Enhanced EMI Shielding and Filtering

Drone manufacturers can integrate better EMI shielding into their designs using conductive coatings, shielded enclosures, and shielded cabling for sensitive electronic components. Similarly, farm equipment manufacturers can build greater immunity into their systems. Filtering techniques can also be employed to block unwanted electromagnetic noise from entering critical circuits.

Proper Grounding and Bonding

Effective grounding and bonding techniques for both drones and farm equipment are crucial. These methods help to dissipate unwanted electromagnetic energy, preventing it from interfering with sensitive electronics.

Frequency Management and Spectrum Planning

Careful management of operating frequencies for both drones and farm equipment can help minimize overlap and reduce interference. This includes selecting communication channels that are less congested or inherently more robust against common EMI frequencies.

Equipment Testing and Certification

Regular testing of drones and farm equipment for electromagnetic compatibility (EMC) can identify vulnerabilities and ensure compliance with relevant standards. This helps confirm that equipment can operate without generating excessive EMI and is immune to expected levels of external interference.

Operational Best Practices

Farmers and drone operators can implement practices to reduce EMI risks:

- Maintain Distance: Avoid operating drones too close to sensitive farm equipment or known sources of strong EMI like high-voltage power lines, cell towers, or power substations.

- Pre-flight Inspections and Calibration: Conduct thorough pre-flight inspections and calibrate drone sensors, especially IMUs, in an area free from strong magnetic interference to ensure optimal performance.

- Risk Assessment: Develop and utilize risk assessment matrices to identify potential EMI hazards in specific operating environments and formulate mitigation strategies.

Regulatory Compliance and Standards

While specific EMI regulations for drones impacting farm equipment are still evolving, adhering to broader drone operation regulations (like FAA Part 107 and Part 137 in the US for commercial agricultural drone use) sets a baseline for safe and responsible operation. These regulations often include requirements for pre-flight inspections and maintaining visual line of sight, which can indirectly help in identifying and responding to potential interference issues.

Future Outlook

As both drone technology and precision agriculture continue to advance, the challenge of EMI will remain a critical area of focus. Ongoing research aims to develop more robust and resilient drone systems with enhanced inherent electromagnetic compatibility. Innovations in materials science for shielding, advanced filtering algorithms, and intelligent frequency hopping technologies will play a significant role. Furthermore, the development of real-time EMI detection systems and smart farm infrastructure that can actively manage electromagnetic environments will be essential to ensure seamless and safe integration of these transformative technologies.

Conclusion

The promise of precision agriculture, empowered by drones, is immense. However, realizing its full potential requires diligent attention to the invisible threat of electromagnetic interference. From disrupting crucial GPS signals to causing operational failures in sophisticated farm machinery, drone EMI poses real risks to efficiency, profitability, and safety. By understanding the sources of interference, recognizing the susceptibility of modern farm equipment, and implementing comprehensive mitigation strategies—from design-level shielding to operational best practices—stakeholders in aerospace engineering and agriculture can work collaboratively to harness drone technology effectively, ensuring a productive and interference-free future for farming.