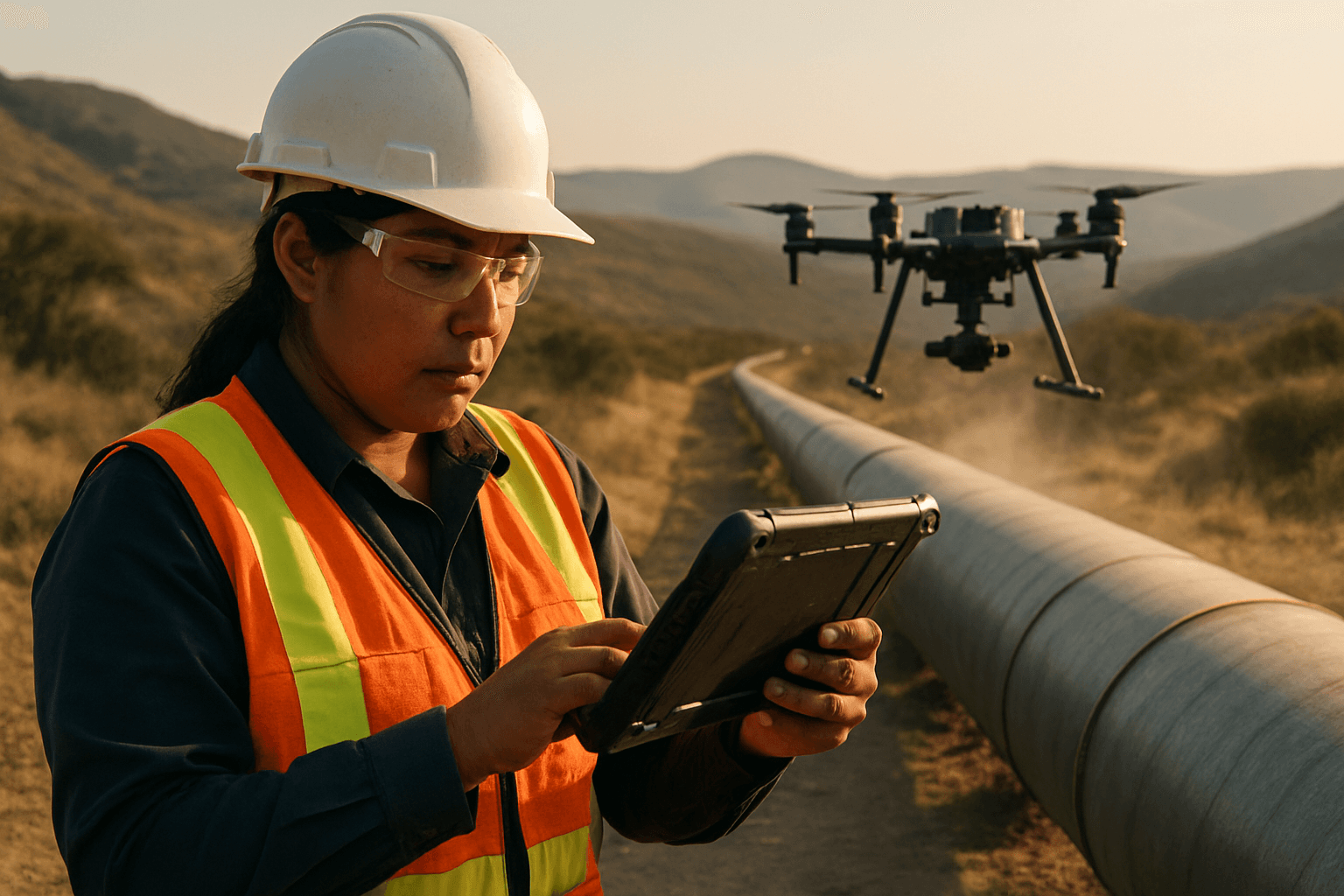

Drones are increasingly being adopted for inspecting gas pipelines, offering a safer, more efficient, and cost-effective alternative to traditional inspection methods for detecting leaks. This technological advancement addresses the challenges posed by vast pipeline networks spanning diverse and often hazardous terrains, improving both operational safety and environmental protection.

The Imperative for Gas Pipeline Inspection

Natural gas pipelines are critical infrastructure, distributing gas to millions of homes and businesses. However, gas is a combustible and explosive substance, making regular monitoring essential to prevent leaks that can lead to significant safety hazards, environmental damage, and economic losses. A small leak can result in substantial product loss and irrevocably damage a wide area. Traditional inspection methods, such as foot patrols and crewed aircraft (like helicopters), are time-consuming, labor-intensive, expensive, and expose personnel to dangerous conditions.

How Drones Enhance Leak Detection

Drones, or Unmanned Aerial Vehicles (UAVs), are equipped with advanced sensors and cameras to monitor and survey pipelines for faults, corrosion, and, crucially, leaks. They provide real-time aerial surveillance and can cover extensive pipeline corridors swiftly, even in challenging terrains where manual access is difficult or impossible.

Advanced Sensor Technologies for Leak Detection

Modern inspection drones utilize a range of sophisticated payloads to identify gas leaks:

- Thermal Imaging Cameras (Optical Gas Imaging – OGI): These cameras detect minute temperature differences on the surface of pipelines. Escaping gas or fluids often alter the temperature around the release point, allowing thermal cameras to pinpoint leaks with remarkable accuracy. OGI technology makes otherwise invisible gas emissions appear as smoke-like plumes on a screen, enabling rapid scanning of large areas without disrupting operations. Drones equipped with OGI cameras can identify methane and other industrial gases safely from a distance.

- Laser-Based Methane Detectors: Tunable Diode Laser Absorption Spectroscopy (TDLAS) systems mounted on drones can detect methane molecules by sending a laser beam to the ground and analyzing the reflection. These systems can identify methane from distances of up to 100 meters, with some advanced models offering a 300-meter detection range and rapid response times. They provide real-time quantification data and can pinpoint the exact leak source, allowing for immediate targeted action. Companies like Bridger Photonics have launched drone-based deployments of their Gas Mapping LiDAR (GML) technology for precise methane emission monitoring.

- Integrated Multi-Sensor Systems: Beyond dedicated gas detection, drones for pipeline inspection often combine high-resolution visual (RGB) cameras, thermal cameras, and LiDAR scanning capabilities. This multi-sensor approach allows for comprehensive data collection, identifying not only leaks but also corrosion, cracks, structural weaknesses, and even vegetation encroachment that could obscure leaks. AI and edge computing can process this data in real-time to alert central operations to potential issues.

Operational Advantages

The integration of drones into pipeline inspection offers numerous benefits:

- Enhanced Safety: Drones significantly reduce or eliminate the need for human personnel to enter hazardous environments, minimizing exposure to toxic gas emissions, extreme temperatures, and dangerous terrains.

- Speed and Efficiency: Drones can cover vast distances and difficult-to-access locations much faster than traditional methods, drastically cutting down inspection times. Automated flight planning and longer flight times enable them to cover large areas in a single mission.

- Cost-Effectiveness: By reducing labor, equipment, and operational disruptions, drones offer a more affordable solution compared to manual surveys, scaffolding, or chartered aircraft.

- Improved Data Quality and Predictive Maintenance: Drones capture high-resolution imagery and detailed sensor data, enabling more precise detection of even small defects. This allows for early leak detection and proactive maintenance, preventing major incidents and costly downtime.

- Regulatory Compliance: Regular, documented drone inspections assist companies in meeting stringent safety standards and environmental regulations, such as API 570 and EPA requirements for fugitive emissions. The EU Commission’s strategy to reduce methane emissions also calls for enhanced leak detection, for which drones are well-suited.

Challenges and Future Outlook

Despite the significant advantages, drone-based pipeline inspection still faces certain challenges. These include navigating complex airspace regulations, particularly for Beyond Visual Line of Sight (BVLOS) operations which often require special permissions. Weather conditions like high winds, rain, or extreme temperatures can also limit drone operations, and battery life might necessitate multiple drones or frequent battery changes for very long pipelines. Additionally, managing, storing, and analyzing the massive volumes of data collected by drones requires robust backend systems.

However, advancements in drone technology are continuously addressing these limitations. The future of drone-based pipeline inspection is promising, with ongoing developments in sensor technology, AI-powered analytics for automated detection, and integrated data management solutions. As these technologies evolve, drones will continue to play an increasingly vital role in ensuring the safety, integrity, and environmental responsibility of global gas pipeline networks.