The towering structures of wind turbines are critical to the global shift towards renewable energy, yet their immense height and exposure to harsh elements make their inspection a challenging, costly, and often hazardous task. Traditionally, inspections involved manual climbing, rope access, or expensive manned aircraft, posing significant safety risks to personnel and leading to considerable downtime for energy production. However, the advent of Unmanned Aerial Systems (UAS), or drones, has revolutionized this process, offering a safer, more efficient, and incredibly precise alternative for assessing the structural integrity and operational status of wind turbine components.

This guide delves into the methodology of conducting an effective drone survey for wind turbine inspection, highlighting the necessary equipment, procedural steps, and crucial considerations for success in this specialized application of UAS technology.

Why Drones are Revolutionizing Wind Turbine Inspection

Drones have emerged as game-changers in wind farm maintenance, transforming the landscape of inspection with multifaceted advantages over traditional methods.

Enhanced Safety and Reduced Risk

Perhaps the most compelling benefit of drone inspections is the dramatic improvement in safety. By eliminating the need for human workers to climb towering structures or operate heavy machinery at height, drones mitigate the risks of falls and other accidents in hazardous environments. Pilots can safely operate the drone from the ground, removing personnel from dangerous situations.

Unmatched Efficiency and Cost Savings

What once took hours or days can now be completed in minutes with drones. A single drone and operator can inspect multiple turbines in a single day, a task that would require significantly more time and resources using traditional methods. This rapid deployment and data capture translate directly into reduced turbine downtime, minimizing lost energy generation and leading to significant operational cost savings. Studies suggest drones can reduce inspection time by up to 70%.

Superior Data Quality and Precision

Drones equipped with high-resolution cameras and specialized sensors can capture data with an unprecedented level of detail, identifying issues that human eyes might miss. They can photograph wind turbines from any angle or location, providing comprehensive visual and thermal data for thorough analysis down to the millimeter. This precision enables early detection of minor damages like micro-cracks, erosion, and lightning strikes, facilitating timely maintenance and preventing costly escalation.

Essential Equipment for a Drone Wind Turbine Survey

Successful drone inspection hinges on using the right tools, combining robust drone platforms with advanced sensor technology.

Advanced Drone Platforms

Industrial-grade drones are essential for wind turbine inspections due to the challenging environments. Key characteristics include:

- Resilience: Ability to withstand harsh wind farm conditions, including high winds (up to 15-25 m/s or 33-56 mph), salt spray, and extreme temperatures (-10°C to 60°C). Water and corrosion resistance (IP45-IP54 rating) are crucial, especially for offshore operations.

- Flight Capabilities: High-performance flight with precise and enduring capabilities for inspecting structures up to 150 meters high. This includes stable hovering and autonomous flight modes for consistent distance and trajectory around turbine blades.

- Redundancy Systems: Features like dual sensors and multi-propeller safe descent mechanisms enhance safety and prevent crashes in case of failures.

- Popular Models: DJI Matrice series (e.g., M30, M300, M350 RTK) are frequently cited for their stability, advanced features, and payload versatility. Other options include Autel EVO Max 4T XE and DJI Mavic 3 Thermal for their specialized capabilities.

High-Resolution Visual and Thermal Cameras

These are the primary data collection tools:

- High-Resolution RGB Cameras: Visible light cameras with ≥20MP resolution and often 40x zoom are necessary to capture surface defects like cracks, erosion, and peeling paint.

- Thermal Imaging Cameras: Thermal sensors (≥640×512 pixels) are crucial for detecting subsurface issues such as delamination, water ingress, overheating bearings, electrical issues, and worn-out parts that may not be visible to the naked eye.

- Lighting: For low-light conditions or internal turbine inspections, auxiliary lights or spotlights can be integrated.

Specialized Sensors and Software

Beyond standard cameras, other technologies enhance inspection depth:

- LiDAR/Ultrasonic Sensors: These non-destructive testing (NDT) tools can measure blade thickness, detect internal damage, and create 3D models for detailed analysis.

- GPS and GNSS Navigation: Ensure accurate and stable drone navigation and precise positioning.

- AI and Machine Learning Software: Onboard or cloud-based AI can automatically identify, classify, and localize defects, turning raw images into actionable insights and streamlining reporting. This allows for predictive maintenance and optimized scheduling.

Step-by-Step Guide to Conducting a Drone Wind Turbine Survey

A successful drone survey involves meticulous planning, precise execution, and thorough data analysis.

Phase 1: Planning and Preparation

- Define Inspection Goals: Clearly outline what needs to be inspected (e.g., blades for erosion, tower for corrosion, nacelle for oil leaks) and the level of detail required.

- Site Assessment and Risk Analysis: Evaluate the wind farm environment for potential hazards, including wind conditions, obstacles, and restricted airspace. For offshore sites, acknowledge the increased complexity due to strong winds and logistical challenges.

- Regulatory Compliance: Ensure all operations adhere to local aviation regulations (e.g., FAA, EASA, CAAC), obtain necessary permits, including Beyond Visual Line of Sight (BVLOS) if required, and ensure data privacy compliance.

- Flight Planning:

- Automated Flight Paths: Utilize software to create precise, automated flight trajectories around each turbine, maintaining consistent distance and optimal camera angles. This is particularly crucial in challenging environments.

- Turbine Downtime: Coordinate with wind farm operators to schedule inspections during minimal downtime. While drones significantly reduce downtime, turbines often need to be taken offline for inspection, especially for close-up blade examinations.

- Pre-Flight Checklist: Thoroughly check drone equipment, including battery life, camera functionality, sensor calibration, and propellor integrity.

- Team Briefing: Establish clear communication plans and review safety standards with the entire inspection team. Ensure pilots are licensed and certified.

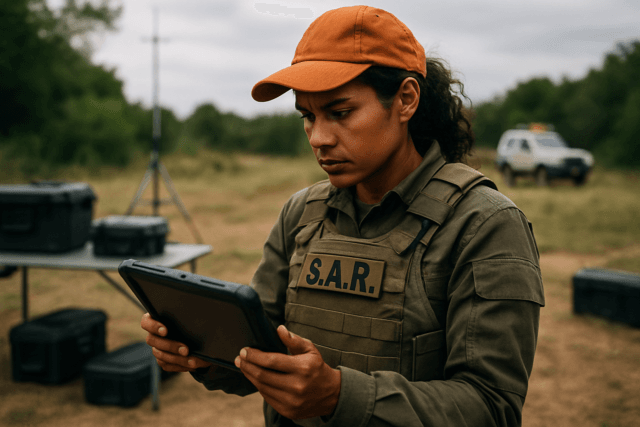

Phase 2: On-Site Execution and Data Capture

- Deployment: Arrive at the location and launch drones from a safe, designated area. Autonomous drones can often self-launch.

- Blade Positioning: For detailed blade inspections, each blade is typically positioned at 12 o’clock (upwards) or 6 o’clock (downwards) to allow the drone to capture full surface data.

- Controlled Flight: Execute the pre-programmed flight paths. The drone will automatically navigate around the turbine, capturing high-resolution visual and thermal imagery of the blades, tower, and nacelle. Manual piloting by an experienced operator may still be required for specific detailed anomalies or in challenging conditions.

- Real-time Monitoring: Ground control stations allow operators to monitor the drone’s flight, view real-time data, and adjust as needed, ensuring all critical areas are covered.

- Data Verification: Before leaving the site, conduct a preliminary check to ensure all necessary inspection data has been captured and is free from errors.

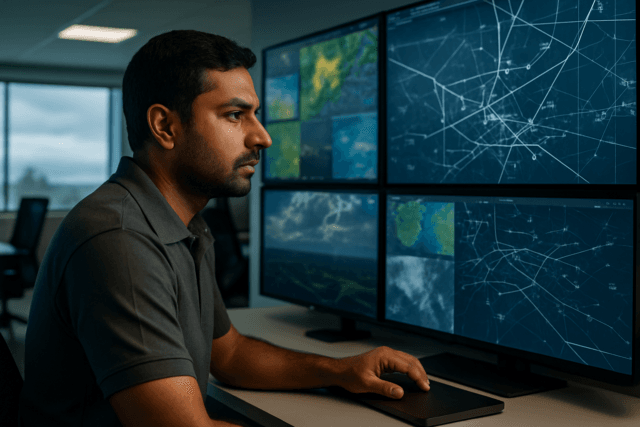

Phase 3: Data Analysis and Reporting

- Data Upload: Transfer the captured images and thermal data to a cloud-based platform or dedicated software.

- AI-Powered Analysis: Utilize AI and machine learning algorithms to process the data, automatically detect defects, and classify their types (e.g., cracks, erosion, lightning damage, delamination). This significantly expedites the analysis process.

- Human Validation (Human-in-the-Loop): While AI excels at initial detection, human experts review and validate the identified defects and classifications. This crucial step ensures accuracy and provides nuanced insights that AI alone might miss.

- Detailed Reporting: Generate comprehensive reports that include annotated images, defect locations, severity classifications, and maintenance recommendations. These reports serve as valuable guides for maintenance teams and can also be used for insurance claims.

- Predictive Maintenance Integration: Integrate inspection data with wind farm management systems to track damage progression over time and optimize future maintenance schedules, extending the lifespan of wind assets.

Navigating Safety and Regulatory Compliance

While drones enhance safety, their operation still requires strict adherence to regulations and robust safety protocols.

Adhering to Aviation Regulations

Drone operators must comply with national and international aviation authorities such as the FAA (Federal Aviation Administration) in the US, EASA (European Union Aviation Safety Agency) in Europe, or CAAC (Civil Aviation Administration of China). This includes pilot certifications, drone registration, and securing operational permits for flights within wind farm airspace. Specific permits, like those for Beyond Visual Line of Sight (BVLOS) operations, may be necessary for large wind farms.

Implementing Robust Safety Protocols

Beyond regulations, practical safety measures are paramount:

- Trained and Certified Pilots: Only certified and experienced drone pilots should conduct wind turbine inspections, especially given the complexities of navigating near large, moving structures.

- Emergency Protocols: Drones should have pre-defined emergency response systems, including obstacle avoidance, weather-related pauses, and manual takeover capabilities.

- Communication: Clear and constant communication between the drone team and wind farm operators is essential, particularly for scheduling and safety during turbine shutdowns.

- Weather Monitoring: Continuous monitoring of wind speed and direction is critical, as conditions can change rapidly and unexpectedly near turbines. Drones should only operate within their specified wind resistance limits.

The Future of Wind Turbine Inspection: AI and Automation

The evolution of drone technology continues to push the boundaries of wind turbine inspection. The integration of advanced AI and machine learning is making inspections not just faster and safer, but also smarter. Autonomous drones, capable of self-launching and following predefined flight paths with minimal human intervention, are becoming increasingly common. These intelligent systems can automatically detect and classify defects, quantify damage, and even track the proliferation of damage over time, contributing to more proactive and predictive maintenance strategies. The ability to create digital twins of entire wind farms, combining drone data with other operational insights, promises even deeper understanding and optimization of wind energy assets.

Conclusion

Conducting a drone survey for wind turbine inspection is a sophisticated process that leverages cutting-edge technology to address the inherent challenges of maintaining these vital renewable energy assets. From enhanced safety and significant cost savings to superior data quality and predictive maintenance capabilities, drones are undeniably transforming the wind energy sector. By meticulously planning, utilizing specialized equipment, adhering to stringent safety protocols, and embracing advanced data analysis, wind farm operators can harness the full potential of UAS technology to ensure the longevity, efficiency, and sustained performance of their wind turbines.