Agricultural drones have rapidly transformed precision farming, offering unprecedented insights and efficiencies in crop monitoring, spraying, and field analysis. However, the demanding and often harsh farm environment—characterized by dust, moisture, chemicals, and variable temperatures—necessitates rigorous maintenance to ensure these valuable assets operate at peak performance and achieve a long lifespan. Ignoring proper care can lead to costly downtime, inaccurate data, and premature equipment failure.

Understanding the Agricultural Drone Environment

Drones used in agriculture, particularly spraying drones, face unique challenges. They are exposed to dust, pollen, plant debris, and chemical residues which can accumulate on vital components, leading to reduced efficiency and potential damage. High temperatures, humidity, and the physical demands of carrying payloads further stress the drone’s systems. Therefore, maintenance practices must specifically address these environmental factors.

Fundamental Maintenance Principles

To maximize the longevity and effectiveness of your agricultural drone fleet, integrate the following core principles into your operational routine:

Consult the Manufacturer’s Manual

Always begin by thoroughly reading and understanding the manufacturer’s manual for your specific drone model. This guide contains crucial instructions and guidelines tailored to your equipment.

Implement a Regular Inspection Schedule

Routine inspections are paramount for catching potential issues before they escalate. A multi-tiered approach, including daily, weekly, monthly, and seasonal checks, is highly recommended. For heavily used drones, comprehensive checks and servicing may be needed every 12 months or more frequently.

Maintain Detailed Records

Keep a meticulous logbook of all flights and maintenance activities. Document flight duration, weather conditions, any observed performance issues, and all maintenance performed. This record-keeping helps track component lifespans, identify recurring problems, and plan for future part replacements.

Pre-Flight Preparations: A Critical Checklist

A comprehensive pre-flight checklist is the first line of defense against operational failures and ensures safe, efficient missions.

Drone Body and Frame Inspection

Before each flight, visually inspect the drone’s frame, arms, and landing gear for any visible damage such as cracks, dents, loose components, or bent parts. Ensure all screws, bolts, and locking mechanisms are tight and secure. For folding drones, confirm that arms are fully extended and clasps are securely locked.

Propeller and Motor Examination

Propellers are crucial for stable flight and lift, especially with heavy payloads. Inspect each propeller for chips, cracks, nicks, warping, or deformities. If any damage is found, replace the affected propellers, ideally in pairs, to maintain balance. Ensure propellers are securely attached and correctly oriented (clockwise and counter-clockwise). Manually rotate each motor to check for smooth movement, unusual noises, or vibrations. Check that motor fixing bases are firm and not loose.

Battery Health and Connection

Verify that all drone batteries are fully charged and free from visible damage, swelling, or leakage. Check battery connectors for corrosion or loose connections and ensure they are securely fastened to the drone. It’s best to fly with fully charged batteries for maximum flight time and performance.

Sensor Cleanliness and Calibration

Ensure that all sensors, including camera lenses, radar, and binocular vision sensors, are clean and free from dirt, debris, or fingerprints. Calibrate the compass and Inertial Measurement Unit (IMU) as recommended by the manufacturer. For agricultural drones, calibration of barometer, lidar, radar, sonar, thermal, and multispectral sensors is crucial for accurate data collection.

Spray System Integrity (for spray drones)

For agricultural spray drones, meticulously check the spray system. Inspect the pump, tank, hoses, and connectors for any signs of wear, looseness, corrosion, or leaks. Ensure nozzles are firmly attached, in the correct orientation, and free from blockages.

Remote Controller and Signal

Confirm the remote controller’s battery level is sufficient and that it is properly linked to the drone. Verify a strong GPS signal and RTK status if applicable.

Pre-Flight Hover Test

Every flight should begin with a short hover test for approximately 30 seconds at 5-6 feet from the ground to ensure all systems are functioning correctly and the drone responds to controls as expected.

Environment Assessment

Assess the surrounding environment, noting any potential obstacles like trees or power lines, and consider weather conditions such as wind speed, gusts, rain, and temperature.

Post-Flight Care: Cleaning and Storage

The agricultural environment means drones accumulate dirt, chemicals, and debris rapidly. Thorough post-flight maintenance is vital.

Immediate Cleaning After Each Operation

After every flight, especially spraying operations, immediately clean the drone. Rinse the spray tank, nozzles, and filters with clean water or a suitable neutralizer to remove chemical residues. Dilute any leftover liquid in the sump with a 10:1 ratio of clean water and repeat rinsing over several cycles. Use a pressurized spray to clean tank walls, plumbing, and boom ends, paying attention to residue buildup.

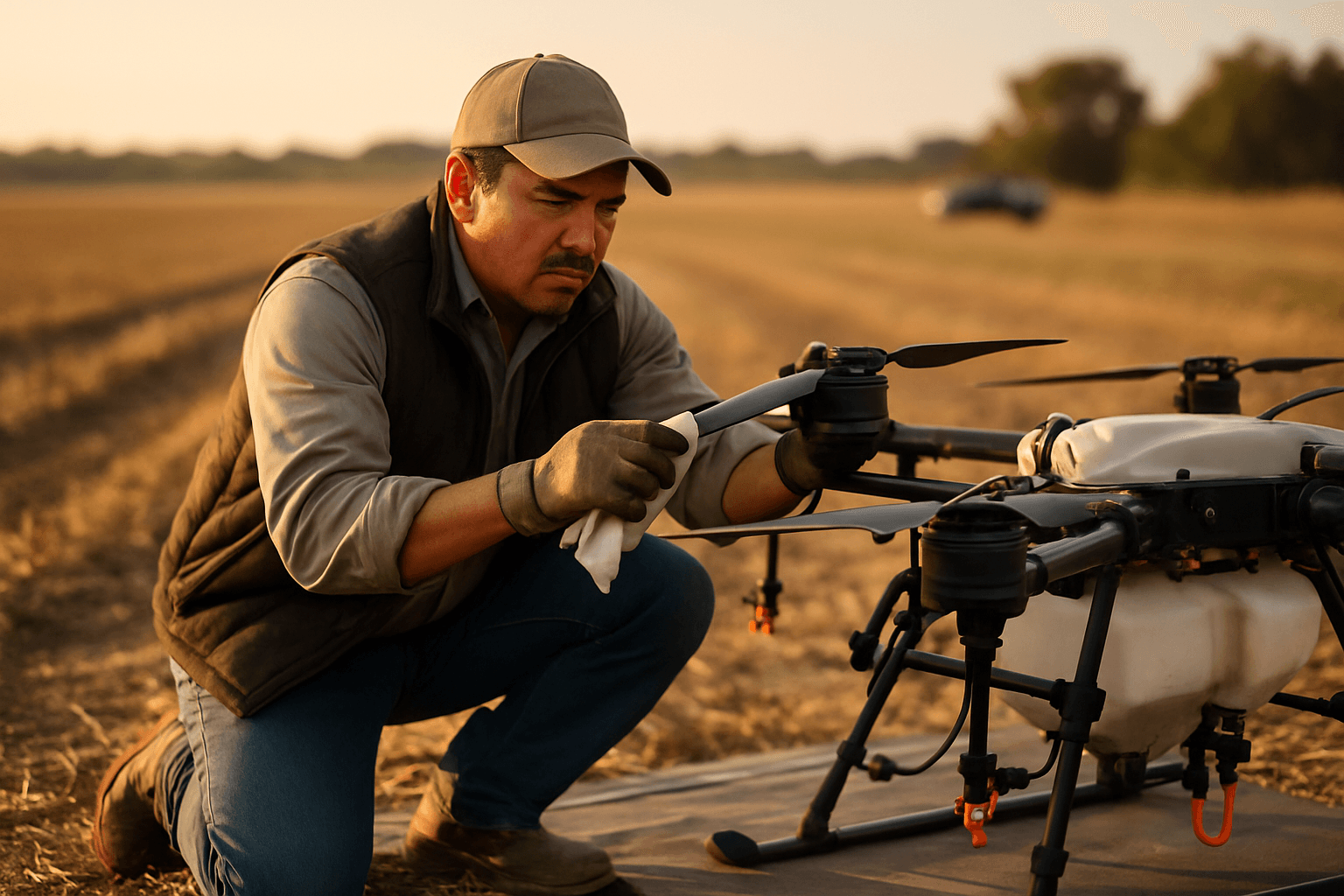

Wipe down the drone’s surface, particularly the propellers, motors, Electronic Speed Controllers (ESCs), and battery distribution board. For motors, use a soft brush or compressed air to remove accumulated dust, sand, grass, or dirt, which can lead to overheating or reduced efficiency. For a more thorough cleaning of motors and power distribution boards, consider using isopropyl alcohol. Crucially, avoid spraying water directly onto the drone or near sensitive electronic components like ESCs, GPS, flight controls, or camera ports.

Battery Management for Longevity

Proper battery care is paramount for performance and safety.

- Cool Down: Allow batteries to cool down to below 40°C before charging after a flight to prevent damage.

- Charging: Always charge batteries within the recommended temperature range using manufacturer-approved chargers. Avoid overcharging or charging too quickly.

- Storage Charge: For short-term storage, charge batteries to 80%. For extended storage (more than 48 hours or seasonal), store LiPo batteries at a partial charge, typically between 40-60% capacity (around 3.8V per cell). This prevents over-discharge or degradation.

- Storage Environment: Store batteries in a cool, dry, and well-ventilated place, away from extreme temperatures (ideal is 15-35°C or 68-86°F), direct sunlight, humidity, and agricultural chemicals. Use LiPo safe bags or fireproof containers for added safety.

- Inspection: Regularly inspect batteries for signs of damage, deformation, swelling, corrosion, or leakage; replace them immediately if any issues are found. Clean battery terminals and charger ports weekly with compressed air or 95% alcohol and a microfiber towel.

- Cycling: Fully charge and discharge batteries (e.g., to 15% charge) at least once every 2-3 months if storing for extended periods to maintain battery activity.

Component-Specific Maintenance Deeper Dive

Motors and ESCs

Beyond regular cleaning, monitor brushless motors for unusual noises or vibrations, which could indicate worn bearings. If detected, bearings may need replacement. Inspect ESCs for signs of overheating, damage, or loose connections.

Propellers

Regular inspection for cracks, chips, or warping is crucial. Replace damaged propellers promptly; minor chips might be normal, but large chips or cracks necessitate replacement. DJI recommends replacing propellers every 700 flight hours. Excessive vibration or a drop in flight time or thrust can also indicate a need for propeller replacement.

Spray System (Nozzles, Pumps, Tanks)

For spray drones, daily cleaning of nozzles, pumps, and tanks is essential to prevent chemical residue buildup that can affect spray accuracy and system performance. Recalibrate the pump and check the flow meter regularly to maintain spray accuracy.

Sensors and Gimbals

Keep all sensors, including those for multispectral imaging and LiDAR, clean to ensure accurate data collection. Calibrate them according to manufacturer guidelines. Gimbals, which stabilize cameras and sensors, should be handled with care and secured during storage to prevent accidental movement.

Software and Firmware Updates

Regularly updating your drone’s firmware and associated software is a critical, yet often overlooked, maintenance task. Manufacturers release updates to fix bugs, improve performance (e.g., flight stability, battery efficiency, GPS accuracy), add new features (e.g., flight modes, imaging capabilities), and ensure compliance with the latest safety and operational standards. Outdated software can lead to performance issues, reduced battery life, inconsistent connectivity, and even crashes. Modern agricultural drone software often includes AI-powered analysis, multispectral imaging integration, and automated flight management, making updates vital for accessing the latest capabilities.

Proper Storage and Transportation

When not in use, especially for extended periods, proper storage protects your investment.

- Protective Case: Store the drone in a protective case or bag designed for its model to shield it from dust, moisture, and physical damage.

- Environment: Choose a dry, clean, and dust-free environment with controlled temperatures, ideally between 15-35°C (68-86°F). Avoid direct sunlight and extreme heat or cold, as these can harm sensitive electronic components and battery performance.

- Spacing: When storing multiple batteries, maintain adequate spacing (0.5 to 0.8 meters) between each to prevent potential hazards.

- Transportation: For transport, especially in agricultural settings, specialized trailers with secure racks and compartments are highly recommended to protect drones and equipment from movement and environmental factors. Secure the drone with straps to prevent forceful jerking that could cause damage.

Conclusion

Effective drone maintenance in agricultural settings is not merely a task but a strategic imperative. By adhering to a disciplined regimen of pre-flight checks, diligent post-flight cleaning, meticulous component care, timely software updates, and proper storage, agricultural professionals can significantly extend the lifespan of their drones, optimize operational efficiency, ensure data accuracy, and ultimately enhance the return on their significant investment in precision agriculture technology.