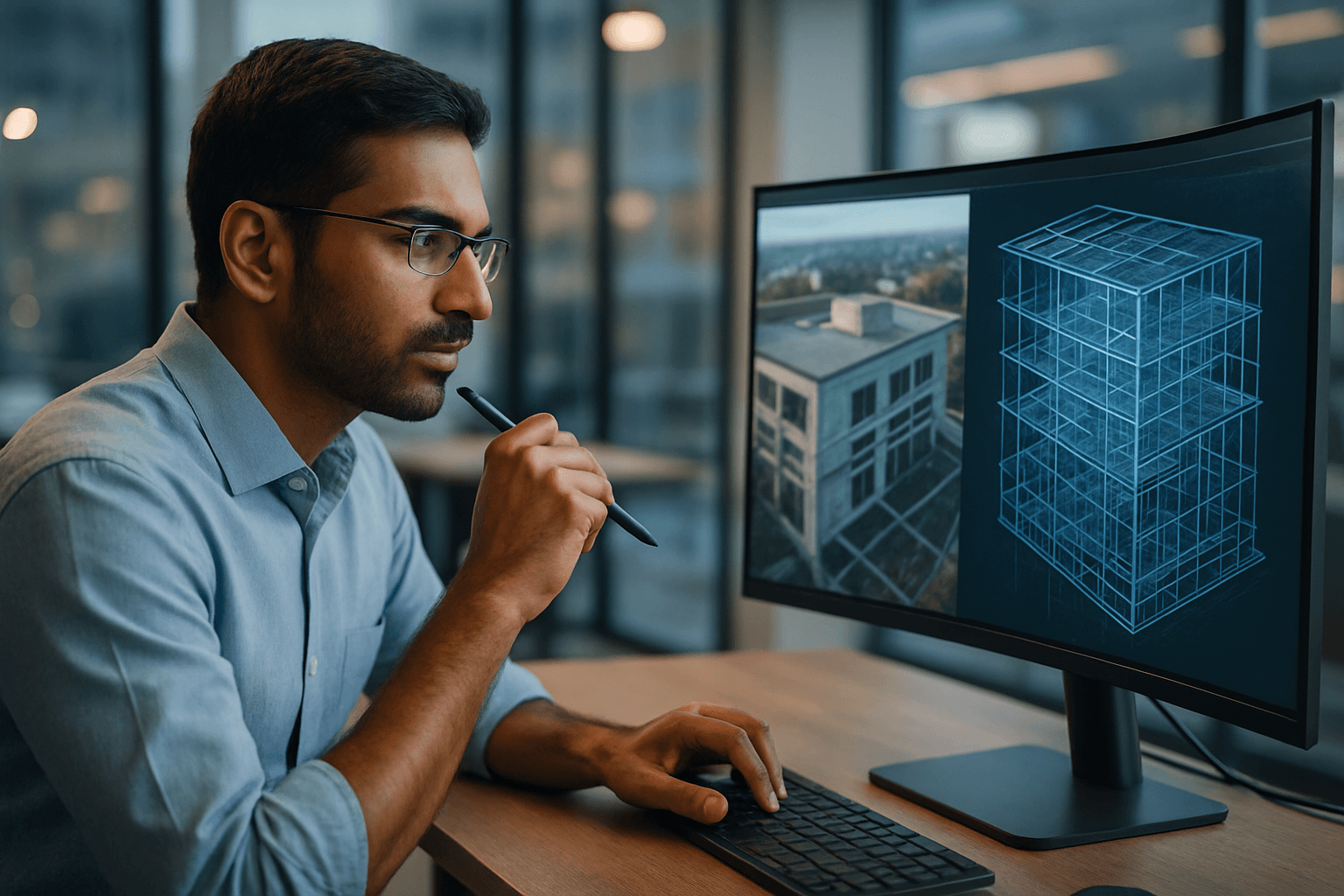

The architecture, engineering, and construction (AEC) industries are undergoing a profound transformation, driven by the convergence of advanced technologies. Among the most impactful integrations is the fusion of drone inspection data with Building Information Modeling (BIM) models. This powerful combination is revolutionizing how projects are planned, executed, and maintained, moving beyond traditional, labor-intensive methods to create a more efficient, accurate, and safer workflow.

Imagine a construction site where real-time progress is continuously monitored, structural integrity is meticulously assessed, and potential issues are identified before they escalate into costly problems. This vision is now a reality thanks to the seamless integration of high-resolution aerial data from drones with the intelligent, data-rich environment of BIM.

The Foundation: Understanding Drone Data and BIM

Before delving into the integration process, it’s crucial to understand the individual strengths of drone technology and BIM.

What is Building Information Modeling (BIM)?

BIM is more than just 3D modeling; it’s a digital representation of a facility’s physical and functional characteristics, serving as a shared knowledge resource for information about a building or infrastructure asset. It integrates data from various sources to create detailed digital models used throughout the entire project lifecycle, from planning and design to construction and post-built monitoring and maintenance. BIM enables real-time collaboration among stakeholders, improves decision-making, and offers greater visibility and transparency in projects.

The Power of Drone-Captured Data

Drones, or Unmanned Aerial Vehicles (UAVs), equipped with advanced sensors such as high-resolution cameras, thermal imaging, and LiDAR (Light Detection and Ranging), can capture vast amounts of precise aerial data quickly and safely. This data provides a comprehensive “bird’s-eye view” and close-up details of inaccessible areas, making drones invaluable for site surveying, inspections, and progress monitoring.

The Integration Process: A Step-by-Step Workflow

Integrating drone inspection data with BIM models typically involves several key stages, transforming raw aerial captures into actionable insights within the BIM environment.

1. Flight Planning and Data Acquisition

The first step involves meticulously planning drone flights to ensure comprehensive data capture. This includes defining flight paths, altitudes, and camera angles.

- Automated Flight Planning: Software can calculate efficient routes to ensure thorough site coverage, optimizing flight time and battery usage, while considering obstacles and weather conditions.

- Sensor Selection: Depending on the inspection’s objective, drones can be equipped with various sensors.

- Photogrammetry: High-resolution cameras capture overlapping 2D images, which are later processed to create detailed 3D models and orthomosaics (geometrically accurate maps).

- LiDAR: Utilizes laser pulses to measure distances, generating highly accurate 3D point clouds, especially useful for complex geometries, challenging terrain, or through vegetation.

- Thermal Imaging: Infrared cameras detect heat patterns, revealing insulation issues, leaks, or electrical faults invisible to the naked eye.

2. Data Processing and Model Generation

Once the drone data is collected, it needs to be processed into usable formats compatible with BIM software.

- Photogrammetry Software: Tools like Pix4Dmapper, Agisoft Metashape, or DroneDeploy are used to stitch together aerial images, generating 3D point clouds, digital elevation models (DEMs), orthomosaics, and textured 3D models.

- Point Cloud Generation: For LiDAR data, specialized software converts the laser scan data into dense 3D point clouds. These point clouds are digital representations of physical spaces made of millions of points, each with unique coordinates.

- Georeferencing: It’s critical to ensure the drone data is accurately georeferenced, meaning it’s precisely aligned with real-world coordinates. This often involves using Ground Control Points (GCPs) for enhanced accuracy.

3. Importing and Integrating into BIM Software

The processed drone data, typically in formats like.rcs,.rcp,.e57,.obj, or.las, can then be imported into BIM authoring tools.

- BIM Software Compatibility: Major BIM platforms like Autodesk Revit, Bentley Systems, and others can import these processed data formats. Autodesk Recap, for instance, can convert point cloud data into.rcp files, making them readable by other Autodesk BIM tools.

- Overlaying and Comparison: The drone-generated point clouds or 3D models are overlaid onto the existing BIM model. This allows for direct comparison between the as-designed model and the as-built or current site conditions.

- Coordinate Transformation: A crucial step involves transforming the drone data’s real-world coordinates (e.g., WGS-84) to the BIM project’s internal coordinate system. Algorithms like F-Trans can simplify this process.

4. Analysis, Annotation, and Actionable Insights

With the drone data integrated, BIM models become dynamic tools for analysis and decision-making.

- Deviation Detection: By comparing drone scans with BIM models, teams can quickly identify discrepancies between planned designs and actual construction, allowing for early corrective action.

- Progress Monitoring: Regular drone flights create a visual record of construction progress, which can be compared against a 4D BIM schedule (3D model with time-related information) to track timelines and identify potential delays.

- Defect Identification: High-resolution imagery and thermal data enable the detection of structural defects, material failures, or thermal anomalies that might otherwise go unnoticed.

- Volume Calculations: Precise topographic data from drones allows for accurate cut and fill volume calculations, helping manage earthwork and material waste.

- Collaboration and Communication: The integrated data in a common data environment (CDE) facilitates transparent communication among all project stakeholders, improving collaboration and informed decision-making. Annotations and modifications within the BIM platform can be instantly accessed by the team.

Benefits of Integrating Drone Inspection Data with BIM

The synergy between drones and BIM offers a multitude of advantages across the entire project lifecycle.

Enhanced Accuracy and Precision

Drones capture data with centimeter-level precision, providing highly accurate 3D models and point clouds that significantly improve the accuracy of BIM models. This precision is critical for detailed measurements and quality control.

Cost and Time Efficiency

Traditional inspection and surveying methods are labor-intensive and time-consuming. Drones drastically reduce the time and manpower required, leading to substantial cost savings. Early detection of issues through drone-updated BIM models minimizes rework and associated expenses.

Improved Safety

Drones can access hazardous and hard-to-reach areas, such as high elevations, active construction zones, or deteriorating structures, eliminating the need for human workers to enter dangerous environments and significantly reducing on-site risks.

Better Project Management and Decision-Making

Real-time insights and comprehensive aerial views from drones, integrated with BIM, provide project managers with a holistic understanding of project status, resource allocation, and potential bottlenecks. This enables proactive management and data-driven decision-making, leading to shorter project timelines and dispute resolution.

Comprehensive Documentation and Digital Twins

Regular drone scans create a living record of the built asset, forming the backbone for digital twins, which are virtual replicas of physical assets. This comprehensive historical data is invaluable for auditing progress, investigating disputes, and for future facility management, maintenance, and renovations.

Challenges and Future Outlook

Despite the numerous benefits, integrating drone data with BIM is not without its challenges.

- Data Alignment Issues: Ensuring accurate georeferencing and seamless alignment between drone data and BIM models can be complex.

- Regulatory Compliance: Drone operations are subject to evolving airspace and safety regulations, requiring licensed pilots and permits in many jurisdictions.

- Processing Overhead: High-resolution drone imagery and detailed BIM files are data-intensive, requiring robust computing power and storage.

- Lack of Standardized Workflows: While advancements are being made, a global standard for drone flight post-processing and BIM integration is still evolving.

The future of drone and BIM integration is promising, with advancements in artificial intelligence (AI) and machine learning (ML) expected to play a pivotal role. AI could enable drones to autonomously perform inspections, identify issues in real-time, and even predict project outcomes. Further integration with Internet of Things (IoT) sensors on-site will enhance monitoring capabilities, combining aerial data with environmental and equipment-level metrics. This continuous evolution promises to make construction projects even more predictable, efficient, and transparent.