The rise of drone delivery services promises to revolutionize logistics, offering unprecedented speed, efficiency, and reach for everything from medical supplies to everyday parcels. However, the operational success and economic viability of these sophisticated fleets hinge on one critical factor: meticulous maintenance. Neglecting proper care can lead to costly downtime, safety hazards, and ultimately, undermine the entire delivery ecosystem. This guide delves into the comprehensive strategies required to keep a drone delivery fleet in optimal, mission-ready condition.

Why Drone Fleet Maintenance is Paramount

For a drone delivery service, every minute a drone is grounded due to a malfunction is a missed delivery and a financial loss. Unlike a single consumer drone, a fleet involves a multitude of aircraft, each accumulating flight hours and experiencing wear and tear. Proactive maintenance is not merely an expense but an investment that extends equipment lifespan, enhances performance, and ensures regulatory compliance. Well-maintained drones can last two to three times longer than those receiving only reactive care, significantly reducing long-term operational costs.

Types of Drone Maintenance for Delivery Operations

Effective drone fleet maintenance incorporates a multi-faceted approach, combining scheduled inspections with responsive interventions.

Preventative Maintenance: Proactive Care for Peak Performance

Preventative maintenance is the cornerstone of a reliable drone delivery fleet. It involves routine, scheduled tasks designed to prevent small issues from escalating into major problems. This often follows a per-flight or flight-hour basis rather than calendar dates, reflecting actual usage and wear.

Key preventative maintenance tasks include:

- Pre-Flight and Post-Flight Inspections: These are the first line of defense, conducted before and after every flight. They involve visual checks of the drone’s frame for cracks or stress points, propeller integrity, battery voltage and cycle checks, and sensor calibration.

- Battery Care: Proper battery management is crucial for drone longevity and safety. This includes monitoring charge levels, storing batteries in cool, dry places, using high-quality chargers, and replacing swollen battery packs. Fully charging and discharging batteries periodically (e.g., every three months) is also recommended.

- Propeller Maintenance: Propellers are subjected to extreme forces and require regular scrutiny. Checks for bends, cracks, chips, or wear are essential, and damaged propellers should be replaced immediately to prevent flight instability. Ensure they spin freely without resistance.

- Chassis and Structural Integrity: Regularly clean the drone’s chassis to remove dirt and debris. Inspect the frame, arms, body, and joints for hairline cracks or loose components, tightening screws and fasteners as needed.

- Motor and ESC Diagnostics: Motors should be regularly cleaned with compressed air to remove dust and debris. Check motor bearings for smooth, silent rotation, as grinding or resistance can indicate wear. Electronic Speed Controllers (ESCs) also require periodic diagnostics.

- Sensor Cleanliness and Calibration: Clean sensors with microfiber cloths to remove dust and fingerprints, which enhances flight accuracy and obstacle detection. Calibrating sensors regularly ensures precise navigation.

- Landing Gear Inspection: Inspect landing gear for cracks, bends, or wear, and ensure shock absorbers are intact and stable to support the drone during takeoff and landing.

- Antenna Checks: Verify that all antennas are secure and in good condition to maintain reliable wireless signals and prevent connectivity issues.

Predictive Maintenance: Leveraging Data for Proactive Intervention

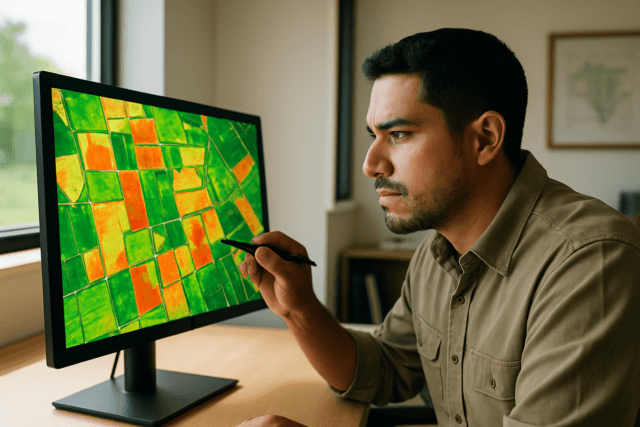

Predictive maintenance (PdM) uses data-driven insights to monitor drone systems and identify potential problems before they escalate. This proactive approach aims to predict component failures and optimize maintenance schedules, reducing unplanned downtime.

Key aspects of predictive maintenance include:

- IoT Sensors and Data Collection: Drones are equipped with sensors that continuously monitor critical components like motors, batteries, rotors, and cameras, collecting real-time data on performance metrics such as temperature, vibration, and power consumption.

- Machine Learning Algorithms: Machine learning models analyze this collected data to detect patterns and anomalies that indicate wear and tear or impending failures. This is particularly useful for predicting battery degradation and remaining useful life (RUL).

- Cloud-Based Analytics and Automated Alerts: Data is often transmitted to cloud platforms for processing and remote monitoring. When anomalies are detected, the system generates alerts, allowing operators to take preventive action.

- Integration with Fleet Management Software: Predictive maintenance insights are integrated into comprehensive fleet management software, enabling optimized resource allocation and minimized downtime.

Corrective Maintenance: Addressing Issues as They Arise

Despite robust preventative and predictive measures, issues can still arise. Corrective maintenance involves immediate action to resolve these problems and restore the drone to operational status. This may include:

- Replacing damaged arms or frames.

- Resolving GPS signal loss or other electronic faults.

- Repairing loose solder joints or other structural damage.

Essential Components of a Drone Delivery Fleet Maintenance Program

Software and Firmware Management

Maintaining a drone delivery fleet extends beyond physical hardware to crucial software and firmware components.

- Regular Updates: Firmware updates are vital for boosting functionality, fixing bugs, enhancing security, and optimizing performance. These updates often introduce new features and stability improvements.

- Fleet Management Software: Comprehensive drone fleet management software is essential for tracking productivity, automating maintenance workflows, and streamlining communication. These platforms can manage tasks like work orders and inspections, monitor expenses, track drone location, and provide overall fleet performance insights. Features often include automated flight management, maintenance tracking, real-time tracking, telemetry, and robust reporting.

- Data Management & Flight Analysis: Software like Airdata UAV helps analyze flight data, identify early signs of potential problems, recommend proactive maintenance, and generate customized reports for compliance and operational improvement.

Regulatory Compliance and Safety Protocols

Adherence to aviation regulations is critical for drone delivery services. Companies must establish exhaustive safety protocols and maintain detailed records.

- FAA Part 135 Certification (in the U.S.): Commercial drone delivery operators in the U.S. typically need to obtain a Part 135 air carrier certificate from the FAA, which involves a rigorous five-phase certification process and often requires waivers for operations like Beyond Visual Line of Sight (BVLOS).

- Airspace Management: Understanding and respecting airspace classifications (controlled, uncontrolled, restricted zones) is crucial. Companies must analyze airspace charts and secure necessary permissions.

- Safety Protocols: These encompass thorough pre-flight inspections, detailed flight planning, advanced collision avoidance technologies, and robust communication systems. Regular checks ensure drones and cargo are in prime condition.

- Record-Keeping: Mandatory record-keeping includes flight logs, maintenance records, and operational hours to meet regulatory reporting requirements.

Training and Personnel

A skilled workforce is indispensable for effective drone fleet maintenance.

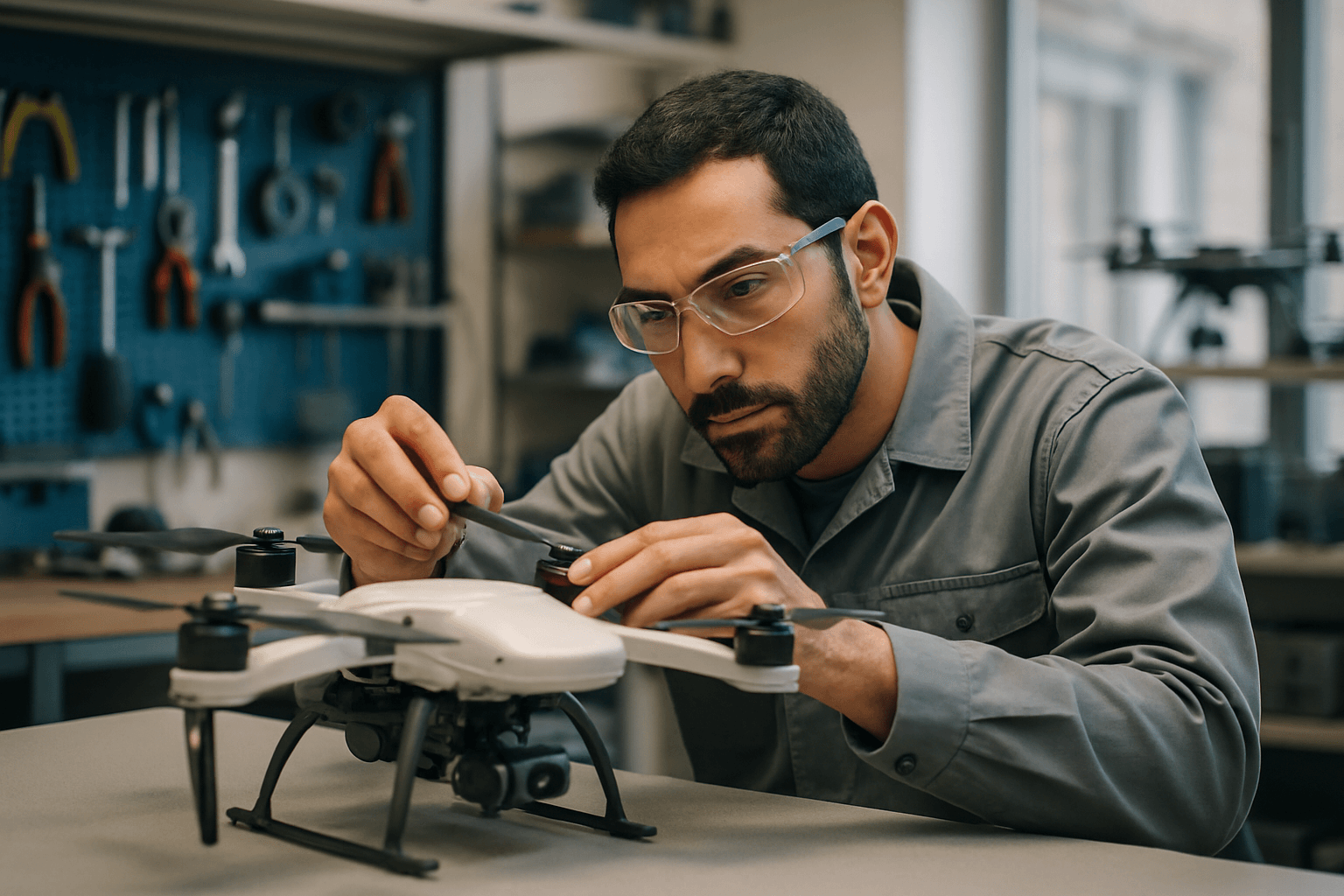

- Maintenance Technicians: Specialized training for maintenance technicians and engineers is crucial. This training covers drone components, flight dynamics, troubleshooting, repairs, assembly, calibration, and configuration of professional drones. Official certifications are often required.

- Pilot Involvement: Drone pilots also play a vital role, conducting pre-flight and post-flight inspections and logging all maintenance activities and flight details.

Logistics and Spares Management

Efficient management of spare parts is essential to minimize downtime.

- Inventory Optimization: An optimized inventory of spare parts, such as propellers, batteries, and motors, is critical to ensure low probability of downtime due to stock-outs.

- Centralized Stock: For larger fleets operating from multiple sites, a central stock can service these locations efficiently.

Emerging Technologies in Drone Maintenance

The field of drone maintenance is continuously evolving, with new technologies promising even greater efficiency and reliability.

- AI-Powered Predictive Maintenance: Artificial intelligence and machine learning are increasingly used to analyze drone data, identify early indicators of wear or damage, and predict remaining useful life for components like batteries and propulsion systems. This allows for maintenance only when truly needed, preventing premature replacements and optimizing operational costs.

- Computer Vision for Anomaly Detection: AI-powered drone inspection systems using computer vision can detect anomalies in components, further enhancing predictive maintenance capabilities.

- Remote Firmware Upgrades: Advanced fleet management platforms allow for remote initiation and tracking of firmware updates across the entire drone fleet, reducing the need for manual intervention.

Maintaining a drone delivery fleet is a complex yet critical undertaking. By implementing a robust, multi-tiered maintenance strategy that embraces preventative, predictive, and corrective measures, leverages advanced software, ensures regulatory compliance, and invests in skilled personnel, companies can unlock the full potential of drone delivery services, ensuring safe, efficient, and reliable operations well into the future.