Drone technology has revolutionized infrastructure inspection, offering unparalleled efficiency, safety, and data accuracy compared to traditional methods. A key component of this revolution is the diverse range of sensors that can be integrated with unmanned aerial vehicles (UAVs) to capture detailed and varied data for comprehensive assessments.

Key Sensor Types for Drone Infrastructure Surveys

The optimal sensor choice for an infrastructure drone survey depends on the specific inspection goals, the type of infrastructure, and the environmental conditions. Here are the leading sensor types:

Visual (RGB) Cameras

High-resolution RGB cameras are the most common and fundamental sensors for drone inspections. They capture detailed imagery and video, essential for visual assessments of structural conditions. This includes identifying visible defects, cracks, corrosion, and general wear and tear on structures like bridges, roads, pipelines, and buildings. Drones equipped with 4K, 6K, and even 8K cameras are increasingly popular, providing sharp and detailed visuals.

Thermal and Infrared (IR) Cameras

Thermal and infrared cameras detect heat anomalies and temperature variations, which are invisible to the naked eye. This makes them crucial for identifying a range of issues, including:

- Insulation failures and heat loss: Detecting energy leaks in buildings and industrial facilities.

- Electrical faults: Pinpointing overheating components in power lines and solar panel installations.

- Moisture detection: Identifying water damage or leaks that might not be visible externally.

- Structural issues: Assessing the status of equipment and identifying potential failure risks in various infrastructure.

Thermal drones allow for operations in low-light conditions and can enhance visibility in smoke or fog.

LiDAR (Light Detection and Ranging)

LiDAR sensors use laser pulses to create highly accurate, detailed 3D maps and models of terrain and objects. They are particularly valuable for infrastructure inspection due to their ability to:

- Generate precise 3D models: Providing a detailed snapshot of an asset that can be compared over time to track changes.

- Penetrate vegetation: LiDAR’s laser pulses can penetrate foliage and other obstructions to capture the ground surface below. This is essential for surveying areas with heavy tree cover, such as power lines or pipelines running through forests.

- Measure distances and elevations accurately: Crucial for topographic mapping, construction site monitoring, and assessing structural integrity.

- Operate in low-light conditions: Unlike visual cameras, LiDAR is less sensitive to natural light conditions, allowing for inspections at night or in poorly lit environments like tunnels.

LiDAR drones significantly enhance safety by reducing the need for manual entry into dangerous or confined spaces and can greatly reduce the time and cost of manual surveys.

Ground Penetrating Radar (GPR)

GPR systems use electromagnetic waves to image what lies beneath the surface without causing disturbance. This non-destructive technology is invaluable for:

- Subsurface utility mapping: Locating and mapping underground utilities such as gas pipelines, water pipes, and cables.

- Bridge and road inspection: Assessing the condition of bridge decks and road surfaces by detecting subsurface defects like delamination, corrosion, or voids.

- Tunnel and subway mapping: Identifying potential hazards, voids, or water ingress along tunnel routes.

- Geotechnical investigations: Mapping soil layers and detecting voids for infrastructure development and environmental planning.

Drone-mounted GPR allows for efficient data acquisition over large areas and can safely access challenging terrains or busy roadways.

Multispectral and Hyperspectral Sensors

These sensors capture data across various specific spectral bands, beyond what the human eye can see (RGB).

- Multispectral cameras typically capture a few distinct spectral bands (e.g., red, green, blue, near-infrared) and are used in precision agriculture, forestry, and environmental monitoring to assess vegetation health and land use.

- Hyperspectral cameras capture dozens or hundreds of narrow spectral bands, providing highly detailed information about the composition and characteristics of objects or surfaces. They are essential for:

- Detailed material analysis: Detecting material degradation, corrosion, or structural issues in infrastructure.

- Pollution detection: Identifying pollutants in water and soil.

- Early sign detection: Identifying subtle changes in vegetation or infrastructure that are not yet visible.

Hyperspectral drones offer high-resolution data and can be used to monitor infrastructure integrity over time.

Ultrasonic (UT) Sensors

Ultrasonic sensors are primarily used for non-destructive testing (NDT) to measure wall thickness and detect surface corrosion or internal defects without harming the material.

- Thickness measurement: Assessing the integrity of tanks, pipes, chimney stacks, and other structures.

- Corrosion and erosion detection: Identifying wall thinning or pitting in pressure vessels and storage tanks.

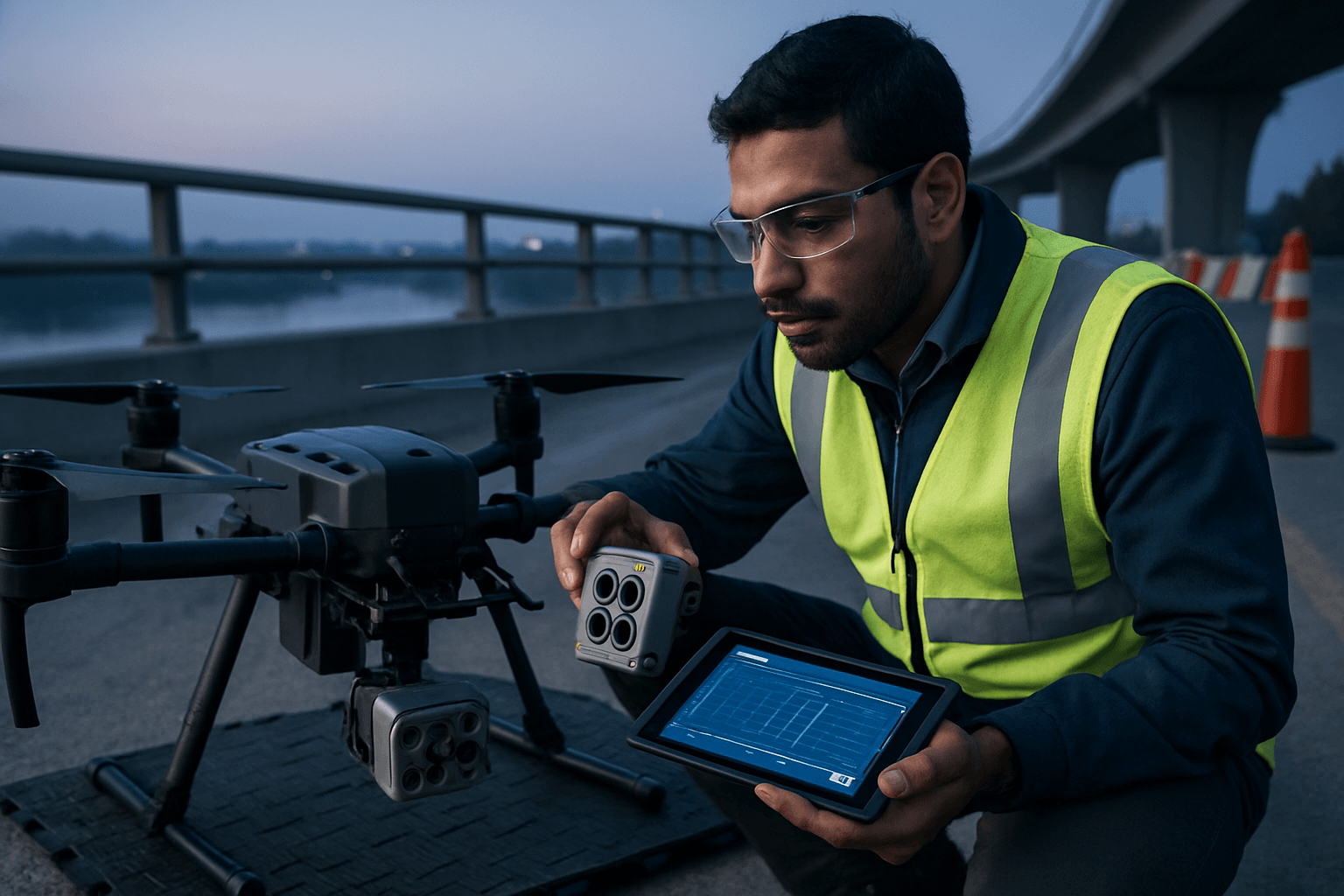

Mounting UT probes on drones allows for safe and quick inspections of elevated or hard-to-reach areas, reducing risks for personnel. Modern UT drone systems can collect live inspection data and feature adjustable sensor arms for dynamic inspection capabilities.

Magnetic Anomaly Detectors (MAD)

Magnetometers, often integrated into Magnetic Anomaly Detection (MAD) systems, measure magnetic fields and their variations caused by metallic objects. While traditionally used for submarine detection, they have emerging applications in infrastructure monitoring for:

- Locating buried metallic components: Identifying buried pipelines or cables that require maintenance.

- Detecting concealed metal objects: Even through walls, underground, or in dense vegetation.

These systems use highly sensitive magnetometers to sense changes in the Earth’s magnetic field.

Factors to Consider When Selecting Sensors

Choosing the best sensors for infrastructure drone surveys involves several considerations:

- Specific Inspection Needs: The type of data required (e.g., visual, thermal, 3D models, subsurface information, material composition) dictates the sensor choice.

- Environment and Accessibility: Factors like light conditions, presence of vegetation, and the ability to access hazardous areas influence sensor selection.

- Required Accuracy and Resolution: Higher resolution and sensitivity in sensors provide more detailed and accurate data.

- Payload Capacity of the Drone: Sensors vary in size and weight, and the drone must be able to carry the selected payload effectively.

- Cost and Budget: Sensor technology varies significantly in price, impacting the overall project budget.

- Data Processing and Analysis Capabilities: The chosen sensors should be compatible with software that can process and analyze the collected data to provide actionable insights.

By carefully considering these factors, infrastructure managers can select the optimal drone sensors to enhance safety, improve efficiency, and ensure the long-term integrity of critical assets.