The colossal structures of offshore wind farms, standing tall amidst unforgiving marine environments, represent a cornerstone of global renewable energy efforts. However, ensuring their long-term integrity, particularly the critical foundations submerged beneath the waves, presents significant operational and safety challenges. Traditionally, these inspections have been hazardous, time-consuming, and costly, often requiring human technicians to work in perilous conditions. Enter drone technology, a game-changer poised to transform how offshore wind farm foundations are inspected, offering a safer, more efficient, and data-rich alternative.

The Imperative of Offshore Wind Farm Foundation Inspection

Offshore wind turbines, including their foundations, are exposed to constant environmental stressors such as saltwater corrosion, strong winds, and powerful waves. Regular and thorough inspections are crucial to detect wear, structural defects, and potential damage early, preventing costly breakdowns and extending the lifespan of these vital assets. Key areas of concern for foundation inspections include identifying:

- Corrosion: Particularly at the splash zone and underwater sections.

- Cracks and Structural Deformations: Which can compromise stability.

- Biofouling: The accumulation of marine organisms that can impact structural integrity and hydrodynamics.

- Erosion: Caused by sediment and water movement.

- Tightness of Anchor Nuts and Bolt Jointings: Ensuring secure connections.

Traditional manual methods involve technicians traveling by boat or helicopter, then using rope access or divers, which are inherently risky, labor-intensive, and often limited in scope.

How Drones Revolutionize Foundation Inspection

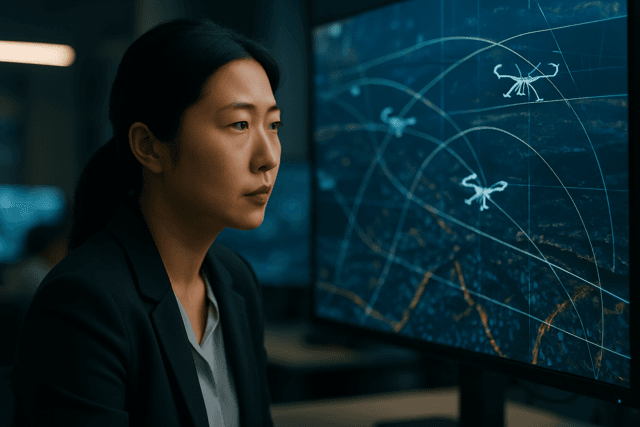

The deployment of unmanned aerial vehicles (UAVs), commonly known as drones, and remotely operated vehicles (ROVs) for underwater sections, is fundamentally reshaping offshore wind farm operations and maintenance (O&M).

Enhanced Safety and Reduced Risk

One of the most significant advantages of drone inspection is the dramatic reduction in human exposure to hazardous environments. By eliminating the need for workers to physically climb structures or dive into the water in potentially dangerous conditions, drones significantly enhance safety and reduce the risk of accidents, including falls from heights or electrical shocks.

Increased Efficiency and Cost-Effectiveness

Drones can perform inspections significantly faster than traditional methods, often completing tasks that would take hours or days in a fraction of the time. Studies suggest a potential 80% reduction in inspection time compared to manual methods, leading to substantial cost savings by minimizing labor and equipment expenses, and reducing turbine downtime. This efficiency allows for more frequent inspections, enabling early detection of issues and proactive maintenance planning.

Superior Data Quality and Comprehensive Coverage

Equipped with advanced sensors, drones capture high-resolution images, thermal readings, and 3D point cloud data, providing detailed insights into turbine conditions. They can access areas that are otherwise inaccessible, ensuring a comprehensive inspection and allowing for the identification of even minor defects before they escalate into major problems.

Key Technologies and Equipment for Drone-Based Inspections

Effective drone-based inspection of offshore wind farm foundations relies on specialized hardware and sophisticated software.

Types of Drones

The choice of drone depends on the specific inspection needs, location, and environmental conditions.

- Multi-rotor Drones: Highly maneuverable and capable of stable hovering, making them ideal for close-up visual inspections of components above the waterline, such as the transition piece and tower base. Examples include the DJI Matrice 350 RTK, known for its extended flight time and durability in offshore locations, and the Skydio X10, which can withstand strong winds.

- Fixed-wing Drones: Better suited for covering large offshore wind farms due to their longer flight times and range, often used for initial surveys or broader area mapping.

- Hybrid Drones (VTOL): Combine the vertical take-off and landing capabilities of multi-rotors with the efficient forward flight of fixed-wing drones, offering flexibility in diverse inspection scenarios.

- Underwater ROVs (Remotely Operated Vehicles): While aerial drones handle above-water structures, ROVs are crucial for inspecting submerged foundation elements and submarine cables. Some have demonstrated autonomous capabilities for assessing exterior conditions and creating 3D models to monitor biofouling.

Advanced Sensor Payloads

The effectiveness of drone inspection is largely dependent on the quality and variety of their sensor payloads.

- High-Resolution Cameras: Essential for capturing detailed visual data, detecting surface defects like cracks, corrosion, and erosion. These cameras often have zoom capabilities for close-up examination.

- Thermal Imaging (Infrared Thermography): Detects temperature anomalies that can indicate internal defects, delaminations, or structural weaknesses beneath the surface of the material.

- LiDAR (Light Detection and Ranging): Provides precise 3D mapping and modeling of the foundation, allowing for the detection of structural deformations, material loss, and accurate geolocation of defects.

- Ultrasonic Sensors: An emerging technique that can detect subsurface defects and assess material integrity, with some drones capable of landing on the structure to perform ultrasonic scans.

AI and Data Analytics

The vast amount of data collected by drones requires sophisticated processing and analysis. Artificial intelligence (AI) and machine learning algorithms are pivotal in this stage:

- Automated Defect Detection: AI-driven algorithms analyze images and sensor data to automatically identify and classify anomalies such as cracks, corrosion, and material degradation with high accuracy. This significantly reduces the time and potential for human error in manual data review.

- Predictive Maintenance: By analyzing historical and real-time data, AI models can predict potential problems before they occur, enabling operators to schedule maintenance proactively, optimize resource allocation, and extend the turbine’s lifespan.

- Digital Twins: Data from drone inspections, including 3D point clouds from LiDAR, can be used to create virtual replicas of the turbines and their foundations, allowing for continuous monitoring and simulation of potential issues.

The Inspection Process: A Step-by-Step Approach

Drone-based inspection of offshore wind farm foundations typically follows a systematic process:

- Planning and Mission Setup: This involves defining the inspection scope, determining flight paths, and programming the drone for autonomous or semi-autonomous operation. Advanced systems can even plan flight strategies based on blade positions.

- Data Acquisition: Drones are deployed from offshore platforms or vessels, flying pre-programmed routes to capture visual, thermal, and LiDAR data. Some systems can automatically take off, land, and even swap batteries from offshore docking stations.

- Data Processing and Analysis: The collected data is uploaded to cloud servers or local processing units. AI algorithms then process this data to identify defects, creating reports and flagging critical issues. Human data analysts review the AI’s findings, interpret trends, and generate actionable insights.

- Reporting and Actionable Insights: Comprehensive reports detailing the condition of the foundation, including the precise location, size, and type of defects, are generated. This information is then used by maintenance crews to plan and execute targeted repairs.

Challenges and Considerations

Despite the numerous benefits, drone inspection of offshore wind farm foundations faces several challenges:

- Weather Conditions: Harsh marine environments with high winds, rain, and waves can affect drone stability, flight safety, and data accuracy, sometimes limiting operational windows. Drones need to be robust and capable of withstanding strong winds and saltwater corrosion.

- Regulatory Landscape: UAV operations, especially in offshore and restricted airspaces, often require special permits and adherence to national and local regulations.

- Initial Investment and Training: Acquiring high-quality industrial drones, advanced sensors, and specialized software represents a significant upfront investment. Additionally, skilled and certified drone pilots and data analysts are essential.

- Battery Life and Range: Offshore locations can be remote, requiring drones with extended battery life or the ability to autonomously recharge to cover large areas effectively.

The Future of Drone Inspection in Offshore Wind

The future of drone inspection in the offshore wind sector is rapidly advancing towards greater autonomy and integration.

- Increased Autonomy and Resident Drones: Future advancements will see more autonomous drones with enhanced navigation and obstacle avoidance, capable of conducting inspections with minimal human intervention. Concepts like “resident drones” deployed from offshore docking stations, automatically conducting inspections and returning for charging, are being developed.

- Integration with Digital Twins: The synergy between drone data and digital twin technology will become more seamless, providing real-time structural monitoring and predictive capabilities for the entire wind farm.

- Cargo Drones: Beyond inspection, cargo drones are being tested for their ability to transport tools and spare parts directly to turbines, streamlining maintenance tasks and reducing the need for costly vessel movements.

Conclusion

Drones are undeniably transforming the inspection and maintenance landscape for offshore wind farm foundations. By significantly enhancing safety, improving efficiency, reducing costs, and delivering superior data quality, they are enabling a more proactive and effective approach to asset management. As drone technology continues to evolve with advancements in AI, sensor capabilities, and autonomy, their role in ensuring the long-term reliability and sustainability of offshore wind energy will only continue to expand.