Maintaining the integrity of vast gas pipeline networks is a critical yet challenging task for the energy sector. Spanning thousands of miles across diverse and often remote terrains, these pipelines are vulnerable to environmental factors, corrosion, and damage, all of which can lead to hazardous and environmentally damaging leaks. Traditionally, inspections have been manual, labor-intensive, costly, and often put human lives at risk. However, the advent of drone technology is rapidly transforming this landscape, offering a safer, faster, more accurate, and cost-effective solution for detecting gas pipeline leaks.

The Imperative for Efficient Gas Pipeline Inspection

Gas pipelines are the arteries of modern energy distribution, delivering natural gas to millions of homes and businesses. Given the hazardous nature of the transported materials, even a small leak can have severe consequences, including environmental damage, economic losses, and potential safety risks to communities. For instance, between 2019 and 2023, pipeline ruptures released nearly 9.7 billion cubic feet of gas into the atmosphere, highlighting the urgent need for more regular and effective inspections. Traditional methods often involve ground crews traversing dangerous terrain or manned helicopters, both of which are expensive, time-consuming, and limited in their visibility and efficiency.

How Drones Revolutionize Leak Detection

Unmanned Aerial Vehicles (UAVs), commonly known as drones, provide an unparalleled platform for non-intrusive and comprehensive pipeline inspection. Their ability to cover extensive distances quickly, access challenging environments, and carry advanced sensor payloads makes them ideal for this demanding application.

Advanced Sensor Technologies for Pinpointing Leaks

Drones can be equipped with a suite of sophisticated sensors specifically designed for detecting gas leaks and assessing pipeline integrity. These include:

- Infrared and Thermal Cameras: Leaking gas can often cause subtle temperature differences in the surrounding area. Drones equipped with infrared or thermal cameras can detect these variations, capturing heat signatures that indicate escaping fluids or gases, even those invisible to the naked eye. These cameras are particularly effective at identifying leaks on solid surfaces, in liquid forms, and even underground by detecting temperature shifts.

- Gas Detectors (Sniffer Technology): Drones can carry specialized gas detectors designed to identify specific types of gases, such as methane, propane, or CO2. These “sniffer” sensors analyze air samples above the pipelines to measure gas concentrations, enabling the detection of even the lightest emissions. Some drones use laser absorption spectrometry to identify gas concentration with high accuracy.

- LiDAR (Light Detection and Ranging) Technology: LiDAR creates accurate 3D maps of infrastructure, which can help identify areas at risk of leakage by revealing changes in the terrain or pipeline structure.

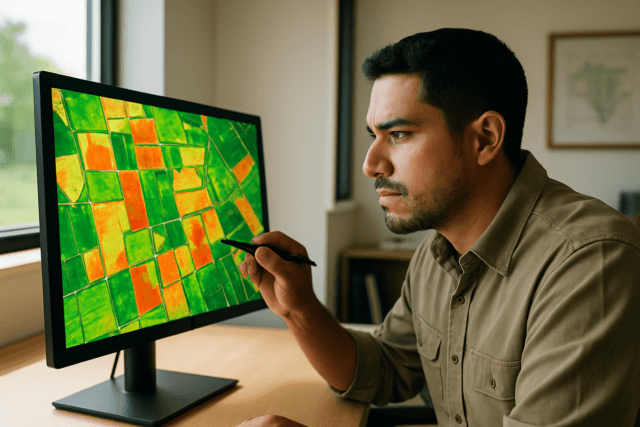

- Hyperspectral and Multispectral Sensors: These sensors can detect subtle chemical changes in vegetation around pipelines that might signal underground leaks or contamination, as leaks can impact plant health.

Enhanced Safety for Personnel

One of the most significant advantages of using drones is the dramatic reduction in safety risks for human inspectors. Drones can operate in hazardous, remote, or inaccessible areas—such as offshore platforms, dense forests, mountainous regions, or areas with potentially toxic gases—without putting personnel in harm’s way. This minimizes risks associated with weather, altitude, and working near volatile materials.

Operational Efficiency and Cost Savings

Drones offer substantial improvements in efficiency and cost-effectiveness compared to traditional inspection methods.

They can:

- Cover vast stretches of pipelines much faster than ground vehicles or even manned aircraft, significantly reducing inspection cycles.

- Reduce the need for expensive resources like helicopters or large ground crews and specialized equipment.

- Shorten inspection times dramatically, with some reports indicating up to 60% faster inspections and 30-40% lower operational costs.

- Enable more frequent inspections without straining budgets, allowing for proactive maintenance rather than reactive repairs.

Improved Data Accuracy and Management

Drones collect high-resolution data that is more consistent and precise than traditional methods. This detailed imagery and sensor data can identify minute cracks, corrosion, deformation, or leaks long before they escalate into critical issues. Data collected by drones can be integrated with asset management and predictive maintenance systems, allowing for comprehensive analysis and long-term monitoring of pipeline integrity. Automated flight paths ensure repeatable results, creating a reliable historical record for analysis.

Environmental Benefits and Compliance

Beyond operational advantages, drones contribute to environmental protection. By enabling earlier detection of leaks, they help mitigate environmental impacts by allowing quicker responses to spills or emissions. Drones also cause less disturbance to sensitive habitats than ground crews and heavy equipment, and by reducing travel for inspections, they can lower carbon emissions. This supports environmental, social, and governance (ESG) objectives and helps companies meet regulatory compliance standards related to environmental protection.

Challenges and Limitations in Drone Pipeline Inspection

While drone technology offers numerous benefits, several challenges need to be addressed for widespread adoption:

- Limited Flight Endurance: Drones typically have limited battery life, with flight times ranging from 30 minutes to a couple of hours for micro UAVs, which can be a constraint for inspecting extremely long pipelines.

- Weather Vulnerability: Drones can be vulnerable to adverse weather conditions such as high winds, heavy rain, or extreme temperatures, which can impact their operation and data collection quality.

- Regulatory Hurdles: Navigating airspace regulations and obtaining necessary permits for commercial drone operations, especially over long distances and varied terrains, can be complex.

- Data Processing and Analysis: The sheer volume of data collected by advanced drone sensors requires sophisticated processing and analytical capabilities, often involving AI and machine learning, to extract actionable insights.

- Beyond Visual Line of Sight (BVLOS): Operating drones beyond the operator’s visual line of sight, often necessary for long pipeline inspections, still presents regulatory and technological challenges.

The Future of Drone-Based Pipeline Inspection

The future of drone technology in gas pipeline inspection is promising, with continuous advancements addressing current limitations. Improvements in battery life, autonomous navigation, and sensor technology will make drones even more efficient and versatile. The integration of artificial intelligence and machine learning is further enhancing their analytical capabilities, allowing for more precise detection, prediction of failures, and automated decision-making. As these technologies mature, drones will become an indispensable tool in pipeline management, ensuring safer, more reliable, and environmentally responsible energy infrastructure.