Dams are critical infrastructure, essential for water management, power generation, and flood control. Their structural integrity is paramount, yet traditional inspection methods often pose significant safety risks, are time-consuming, and can be cost-prohibitive. This is where Unmanned Aerial Systems (UAS), or drones, have emerged as a revolutionary solution, transforming how these vital assets are monitored and maintained. By leveraging advanced drone technology, dam operators and engineers can achieve safer, more efficient, and highly detailed inspections, gaining unprecedented insights into a dam’s condition.

Why Drone-Based Dam Inspections are Essential

The structural health of dams is constantly challenged by factors such as water pressure, temperature fluctuations, freeze-thaw cycles, sediment movement, and material aging. Early detection of subtle deterioration, like minor cracks, surface wear, or moisture staining, is crucial to prevent serious structural issues. Drones address the limitations of conventional inspections by providing access to hard-to-reach or hazardous areas, offering superior data quality, and enabling repeatable monitoring for long-term asset management.

Key Advantages of Using Drones for Dam Inspection

- Enhanced Safety: Drones eliminate the need for personnel to access dangerous areas like steep dam faces, high spillways, or confined spaces, significantly reducing risks associated with working at heights or over water.

- Reduced Time and Cost: Conventional methods often require extensive preparation, including scaffolding or rope access, which is time-consuming and expensive. Drones can cover large areas quickly, reducing both inspection time and associated operational costs.

- Superior Data Quality and Detail: Equipped with high-resolution cameras and specialized sensors, drones can capture consistent, detailed imagery from optimal angles, revealing defects that might be missed during ground-based visual checks.

- Repeatable Monitoring for Trend Analysis: Drones can follow predefined flight paths, allowing for standardized data collection over time. This repeatability enables accurate comparison of datasets, tracking gradual changes, and identifying deterioration trends, supporting proactive maintenance.

- Environmental Benefits: Drones reduce the need for ground-based vehicles, minimizing disruption to wildlife habitats and local ecosystems.

The Comprehensive Process of a Drone Dam Survey

Performing a successful drone survey for dam inspection involves meticulous planning, advanced equipment, adherence to regulations, and thorough data analysis.

1. Pre-Flight Planning and Risk Assessment

Before any drone takes flight, comprehensive planning is essential. This stage sets the foundation for a safe and effective inspection.

- Define Inspection Objectives: Clearly identify what aspects of the dam need inspection (e.g., concrete surfaces, joints, spillways, embankments, drainage systems, intake towers) and what types of anomalies are being sought (e.g., cracks, spalling, seepage, vegetation growth).

- Site Assessment: Analyze the dam’s structure, surrounding terrain, weather conditions, and potential environmental factors (e.g., wind, moisture).

- Regulatory Compliance: Dam inspections typically involve professional-grade drones and often fall under stricter aviation regulations. This may require certified pilots, approved operational procedures, and formal risk assessments depending on the country and mission profile.

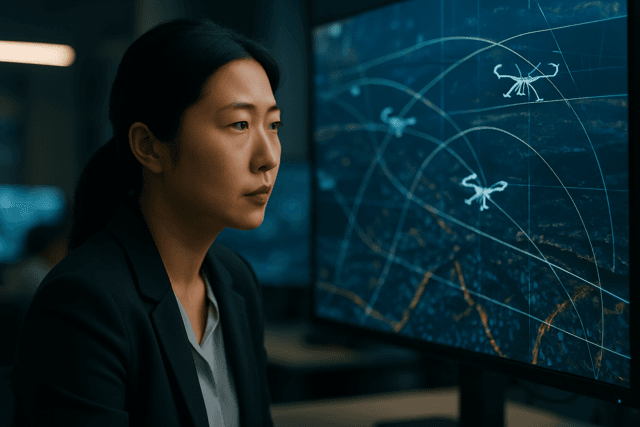

- Flight Path Planning: Utilize automated flight software to pre-set routes. This ensures consistent data capture, optimal overlap for photogrammetry, and efficient coverage of the entire dam structure, including hard-to-reach areas. Ground Control Points (GCPs) should be established to improve absolute positioning accuracy for mapping and modeling workflows.

- Safety Protocols: Establish clear safety protocols, including emergency procedures and communication plans, especially given that dams are critical infrastructure.

2. Equipment Selection

The choice of drone and sensors is critical to capturing the necessary data for a detailed dam inspection.

- Professional-Grade Drones (UAS): Select drones known for stability, precise positioning, endurance, and the ability to carry specialized payloads, especially in challenging environments like those with wind and moisture.

- High-Resolution Visual Cameras (RGB): These are fundamental for capturing detailed imagery to identify visible defects such as cracks, spalling, surface degradation, corrosion, and unwanted vegetation growth.

- Thermal Cameras: Thermal sensors are invaluable for detecting temperature differences that can indicate seepage paths, internal moisture, blocked drainage systems, or abnormal water flow, which are often invisible to the naked eye.

- LiDAR Sensors: For highly accurate 3D modeling and terrain mapping, LiDAR (Light Detection and Ranging) provides precise point cloud data, which is especially useful for deformation analysis and volumetric measurements.

- RTK/PPK Modules: Real-Time Kinematic (RTK) or Post-Processed Kinematic (PPK) GPS systems enhance the geospatial accuracy of the collected data, crucial for precise mapping and monitoring of minute changes over time.

- Underwater Drones (ROVs): For submerged structures, underwater remotely operated vehicles (ROVs) equipped with sonar can detect issues below the waterline, such as sinkholes or structural failures, cost-effectively and safely.

3. Data Acquisition

During the flight, pilots execute the planned mission, ensuring optimal data capture.

- Controlled Flight Paths: Pilots fly controlled and carefully planned paths close to the dam structure, capturing thousands of images from multiple angles.

- Sensor Operation: Ensure all sensors are correctly calibrated and operating to capture high-resolution visual, thermal, or LiDAR data as per the inspection objectives.

- Overlap and Coverage: Maintain sufficient image overlap (e.g., over 70%) to facilitate accurate photogrammetric processing and 3D model generation.

4. Data Processing and Analysis

Once data is collected, it undergoes rigorous processing to generate actionable insights.

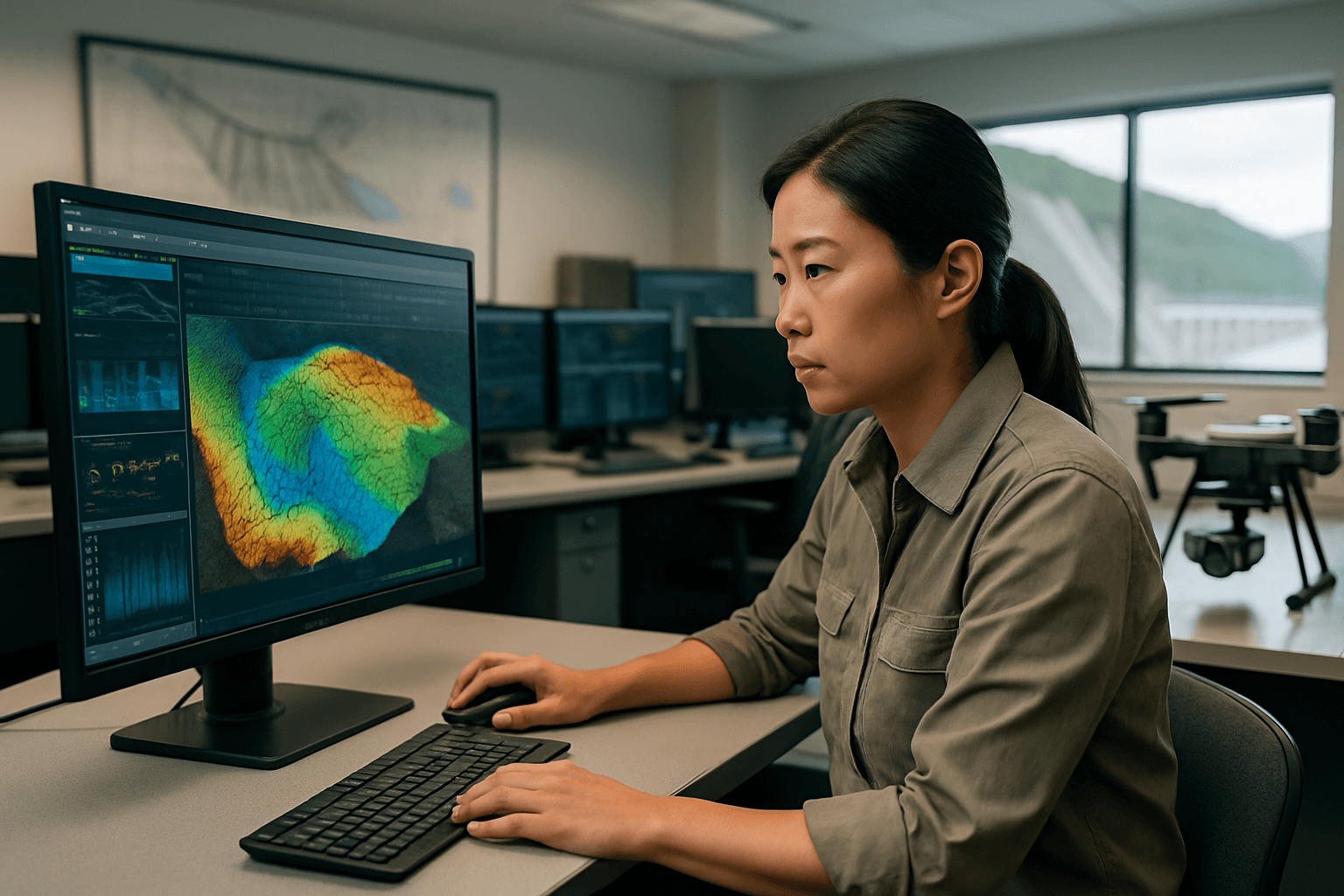

- Photogrammetry and 3D Modeling: High-resolution images are processed using specialized software (e.g., WebODM, DroneDeploy, ArcGIS Site Scan) to create accurate 2D orthophotos and detailed 3D models or “digital twins” of the dam. These models allow for precise measurements, deformation analysis, and visual inspection in a virtual environment.

- Thermal Analysis: Thermal imagery is analyzed to identify hot or cold spots, indicating potential leaks, structural anomalies, or areas of moisture ingress.

- Point Cloud Analysis: LiDAR data generates dense point clouds, which can be used to detect subtle changes in the dam’s geometry, monitor erosion, or identify structural shifts over time.

- Defect Identification and Mapping: Engineers review the processed data, visually identifying and tagging defects such as cracks, spalling, efflorescence, and areas of vegetation growth. Each defect should be precisely located, sized, and assigned a severity level, linking back to the original imagery.

- Change Detection: By comparing current models and data with previous inspections, changes over time can be accurately detected and quantified, facilitating proactive maintenance and long-term asset management.

5. Reporting and Recommendations

The final stage translates the raw data and analysis into comprehensive reports for decision-makers.

- Comprehensive Reports: Compile all findings into a detailed report, including visual data, mapped defects, annotations, and analysis results.

- Actionable Insights: Provide clear, actionable recommendations for maintenance, repair, or further investigation based on the inspection findings.

- Integration with Asset Management Systems: Integrate drone inspection data into existing dam safety and asset management systems for ongoing monitoring and record-keeping.

The Future of Dam Safety

Drones are revolutionizing dam safety inspections by offering a faster, safer, more accurate, and repeatable process than traditional methods. As UAS technology continues to evolve, incorporating advancements like synthetic aperture radar (SAR) systems on drones for detecting sub-millimeter changes, the capabilities for monitoring these critical structures will only expand. The integration of drone technology is not just an enhancement; it’s becoming a standard practice for ensuring the long-term integrity and safety of dams worldwide.